A Real-World Example

A customer ordered three mugs as a gift for a special occasion, choosing to collect the package at a nearby collection point operated by a family-owned bookstore in the Netherlands. Despite the store’s long-standing commitment to excellent service, locating the package proved challenging.

This scenario highlights the complexities and potential inefficiencies in e-commerce fulfillment, even for simple orders.

Mapping the Fulfillment Process

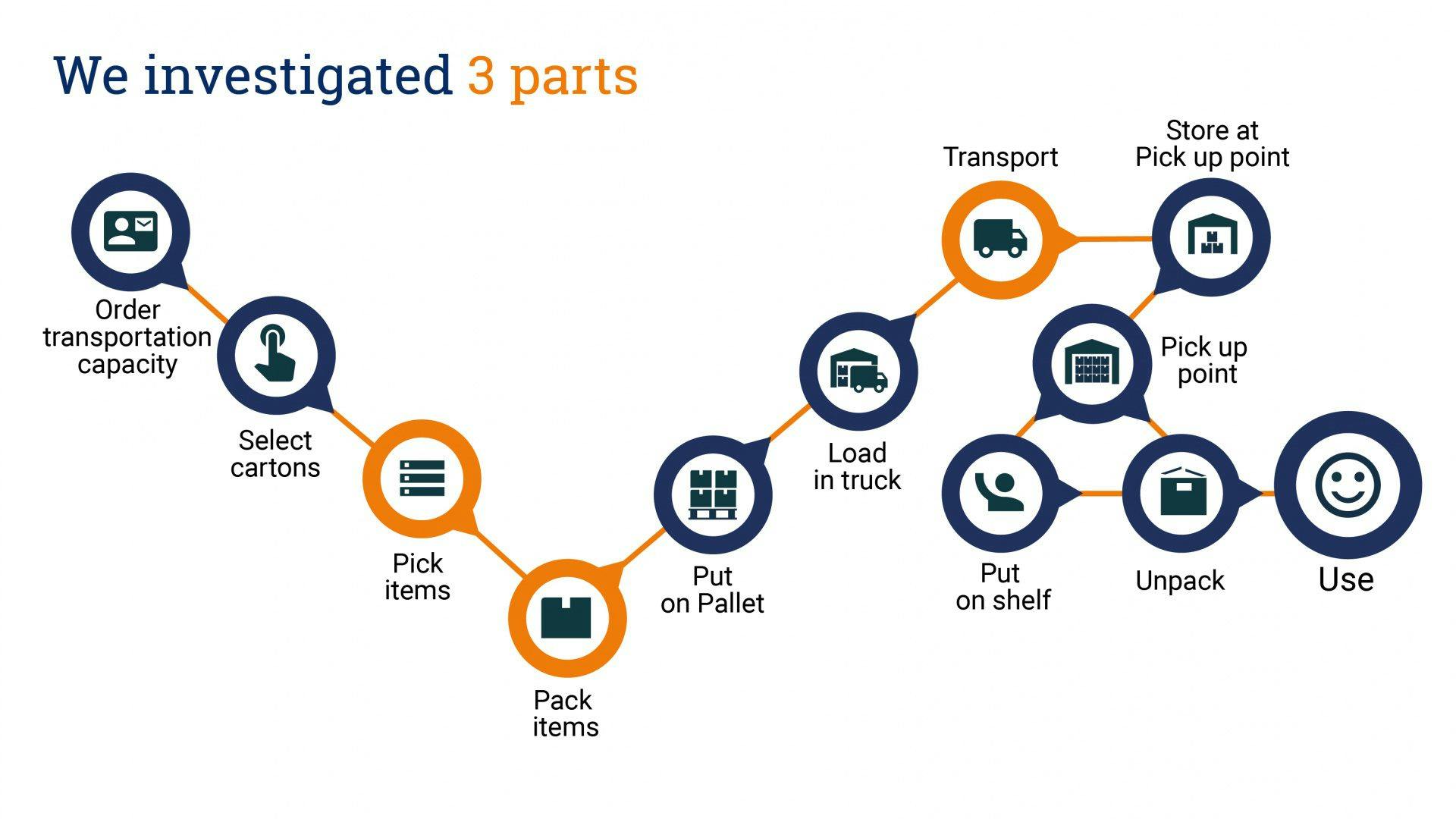

A standard order involves several steps:

- Human activities: picking, packing, and labeling products

- Materials: cartons, filler material, and labels

- Equipment: forklifts, conveyor systems, and delivery trucks

Even minor inefficiencies in these steps can accumulate, leading to higher operational costs and delayed deliveries.

Figure 1: Overview of the e-commerce fulfillment process from order to delivery.

How Waste Occurs in E-Commerce Fulfillment

Errors and delays can occur when shipping addresses are provided, delivery methods are selected, and warehouses manage product locations. Key areas of potential inefficiency include:

- Picking and packing operations

- Carton selection and sizing

- Loading and transportation

Research shows that optimizing shipping carton selection alone can reduce costs by €0.20–€0.50 per national shipment. Applied across multiple shipments, these savings can significantly improve profitability throughout the European supply chain.

One Algorithm, Eleven Steps Optimized

Implementing a smart carton-selection algorithm can optimize logistics across the supply chain. This approach reduces handling errors, improves space utilization, and enhances delivery efficiency. Even small adjustments, such as choosing the optimal package size, can produce measurable cost savings across eleven fulfillment steps.

Figure 2: Highlighted in orange - the steps in the fulfillment process where optimization reduces costs.

Lessons from the Collection Point

In the De Bijenkorf example, the package containing the mugs was larger than expected, requiring storage in a different section of the store. This illustrates that shipping carton size and selection affect efficiency across the entire supply chain, from warehouse operations to last-mile delivery.

Optimizing carton selection reduces handling time, minimizes errors, and saves costs—benefiting both retailers and customers.

Take Action to Reduce Fulfillment Costs

European e-commerce companies can unlock substantial savings by applying advanced logistics algorithms to carton selection and shipment planning. ORTEC’s supply chain experts provide solutions for:

- Cost-effective packaging and loading

- Optimized delivery routes and transportation

- Full supply chain visibility and efficiency