Valuable air: 50% of what we transport is packaged air

“If you have to deliver between one and two million parcels per day, you need prediction models.”

PostNL has four guiding principles in its sustainability transition: CO2 reduction, livability, transparency and transformation, together with both customers and colleagues. Rogier Havelaar, who is responsible for sustainability at PostNL’s largest business unit, identifies three logistics trends: urbanization, new customer demands and data. The company has already been innovating at the intersection between sustainability and business for some time now: “Our targets are aligned with the provisions enshrined in the Paris Agreement; the Science Based Targets initiative (SBTi) has officially established this. We also stated last year that we wanted to accelerate our greening process, and we are investing an additional 80 million euros for that purpose.”

Interview with Rogier Havelaar, Head of Sustainability Parcels & Logistics

“We bought our first electric vehicles in 2014 for urban logistics and in 2016 for regular processes,” recalls Havelaar. “Since then, we’ve been reinventing our entire network. We don’t believe in simply replacing all our diesel vehicles with electric ones; instead, we feel that we should take advantage of this opportunity to further innovate all of our processes. That’s why we’re reexamining all of the links in our logistics process – collection, sorting and distribution – to find out what we can do smarter or differently in our journey towards greater sustainability.”

Valuable air

The postal logistics process starts with collection: “We pick up a great deal of volume from our customers and from our almost 4,000 retail points. Within the cities, we certainly do this as much as possible with the electric vehicles already available to us. We started streamlining processes in 2014 by having drivers not only drop off packages at a retail point, but immediately collect them there too. This saves on transport movements, simultaneously increasing efficiency and sustainability. For bulk transport, we’re looking at how we can remove as much air from packaging as possible. About 50% of what we transport is air packaged in cardboard – I always call it ‘valuable air’! We can have the greatest impact on freight transport by reducing that air. Consumers also frequently ask for less air and more environmentally friendly packaging materials.

Rogier Havelaar, Head of Sustainability Parcels & Logistics

"About 50% of what we transport is air packaged in cardboard – I always call it ‘valuable air’! We can have the greatest impact on freight transport by reducing that air. Consumers also frequently ask for less air and more environmentally friendly packaging materials."

According to Havelaar, investing in prediction models is also part of this step in the process, enabling proper matching of capacity to actual volume. “We try to drive fewer miles in the collection process, and to ensure that those miles are as clean as possible. The CO2 emissions for each parcel are mainly in what’s known as the ‘first & middle mile’, and less in the ‘last mile’ – this is the vehicle that you see when a parcel is delivered to you. The bulk of the CO2 emissions come from the trucks that have driven overnight with your parcel on board. Electric trucks aren’t available yet – or at least, not ones that are capable of driving the distances that we need them to. That’s why we’re focusing on clean fuels for freight transport, such as Bio-LNG and HVO 100.”

Clean and livable

PostNL has 27 sorting centers, the vast majority of which have the highest BREEAM certification. “They have solar panels on the roof, nature-inclusive constructions, and we’ve minimized energy use as much as possible, which means that the sorting process is now completely carbon-neutral. We are also increasing the infrastructure for our vans. You need three things when delivering with electric vehicles: the vans themselves, power, and a place to charge your vans using that power. All three of these components are challenging. You need vans that can travel far enough, you need to be able to charge them and you need to have enough power. Fortunately, we do have all these things, but the increasing congestion on the power grid is adding to the pressure.

Download the magazine

This article is part of the 3rd issue of our magazine Data and AI in the Boardroom. Get your copy now.

We've asked leading figures in different sectors about how their organizations develop into more sustainable businesses, what goals they have set for themselves, what challenges they face underway, and how using data in innovative ways help them to make responsible decisions.

In this issue you’ll catch a glimpse of the approaches by leading figures at organizations like Schiphol Airport, PostNL and Eosta.

Due to continued urbanization, there is also greater congestion on the roads in the Netherlands. Havelaar: “When it comes to distribution, we try to drive as cleanly as possible, and we take livability into account too. In city centers, for example, we deliver early in the morning wherever possible. We work with city hubs at the edge of the city. We are focusing on light electric freight vehicles (LEVs, ed.) for use in historic city centers, where a smaller vehicle allows easier access to narrow streets. Livability also involves the appearance of our vans and drivers, and courteous behavior in traffic. Cargo bikes are very popular in marketing, especially by some of the larger online stores. However, a cargo bike is not an ounce of CO2 cleaner than an electric van. And if I tried to deliver 50,000 parcels a day with cargo bikes in Amsterdam, I would have a fight on my hands with the city's residents – and rightly so. They are already up in arms over what’s happening with lightning delivery services.”

“You need three things when delivering with electric vehicles: the vans themselves, power, and a place to charge your vans using that power. All three of these components are challenging.”

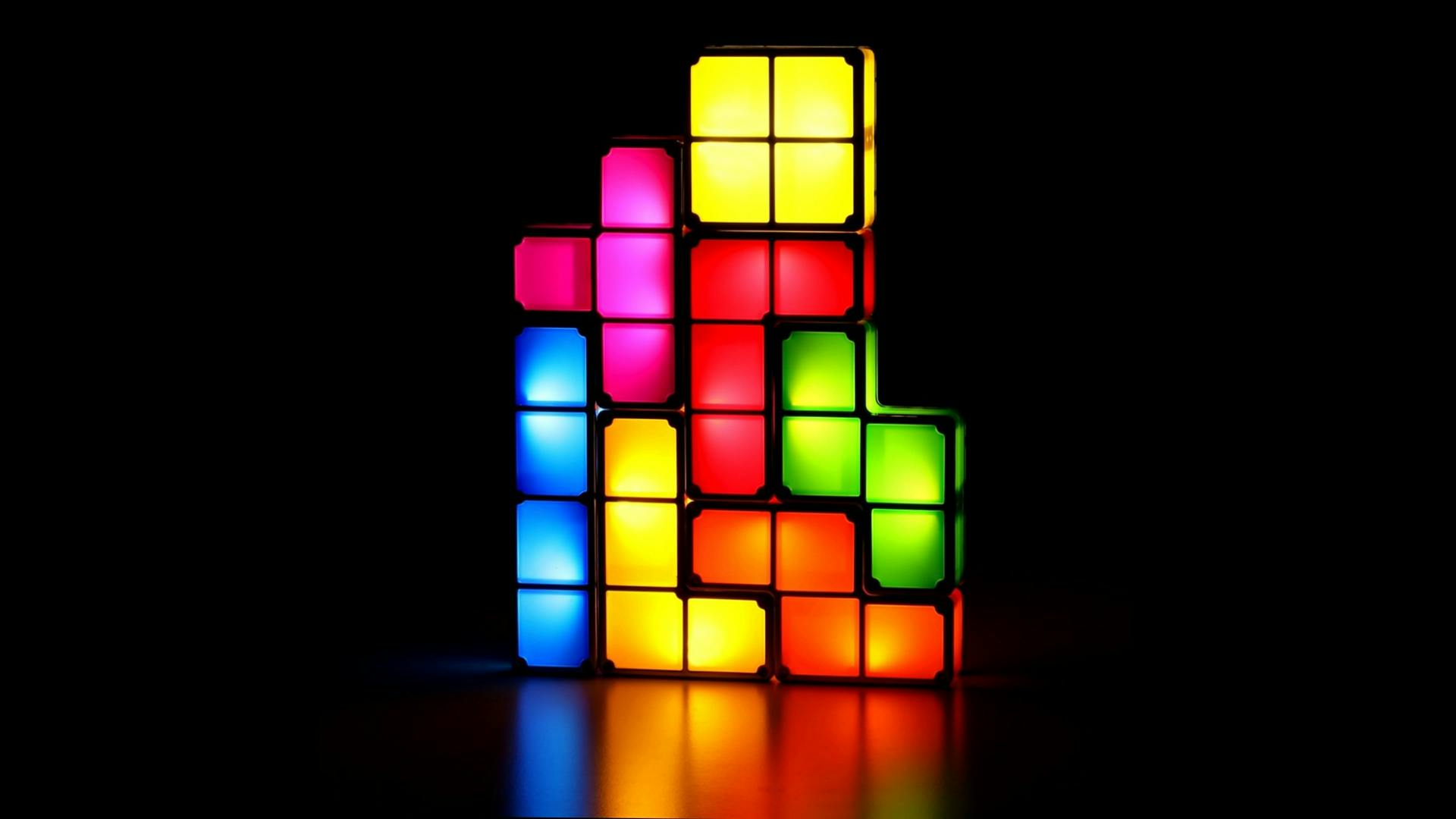

Tetris tool

PostNL has therefore chosen to collaborate with manufacturers on developing its own LEVs. “Using LEVs helps to contribute in a different way to livability, for example large vans stopping every 40 yards would only lead to congestion and irritation. We are currently calculating all the traffic effects of these types of vehicles in the Arnhem, Groningen and The Hague city centers, as well as reinventing our own process. Every additional transshipment point increases the chance of errors, and we really want to avoid that.”

That's why PostNL has created a type of LEV that accommodates two to three roll cages that can already be packed in the sorting plant. “They’ll probably love this at ORTEC: once a parcel comes out of the sorting machine a code is projected onto the package, indicating which container and compartment of that container it should go into. This code is calculated by an algorithm that we wrote ourselves: the Tetris tool. The full roll cages are then sent to a downtown micro-hub and enter the LEV without any human contact. Along the route, the delivery driver is told at each stop where the relevant parcel is in the roll container. This enables us to reduce both the risk of errors and the search time. We are carrying out large-scale testing of this process now.”

Change management

Havelaar believes that ‘his’ organization is special because it implements transformations in collaboration with the market. “In recent years we’ve frequently had to change ourselves, together with 35,000 colleagues. Every Dutch citizen is our customer. In 2010, we implemented the first major changes to the letter network in the corporate market. In both commercial and internal change management, you see that you can never be careful enough. You really have to pay attention to your reasons for doing things. Naturally, we had to make some difficult decisions at PostNL, but we always had our eyes on the prize. The letter operations strategy was to downsize until we were future-proof. That approach has paid off. By contrast, PostNL opted for growth when it came to parcels. We have significantly changed shopping in the Netherlands, and we’ve included the market in that transformation.”

The company has been part of Dutch history for centuries, the sustainability manager emphasizes: “We were founded by Napoleon in 1799. By 2035, we will have delivered special moments for 235 years. We sincerely believe in what we do. Instead of having a transactional approach to our work, we take an emotional approach. We want to be everyone’s first choice as a delivery company. However, we believe that's only possible if you're extremely sustainable, let the customers know that you're there to connect with them, and let the customer decide how, where and when they want to receive their parcel. We’ve therefore invested a lot in digital applications at PostNL, so we can give consumers more control over their own delivery.”

"We want to be everyone’s first choice as a delivery company. However, we believe that's only possible if you're extremely sustainable, let the customers know that you're there to connect them, and let the customer decide how, where and when they want to receive their parcel."

People and data

In the Dutch market, there is still quite a lot of discussion about self-employed parcel deliverers. Havelaar is happy that PostNL has already moved past that discussion a few years ago: “Back then we were working with thousands of self-employed people, and now we have a much smaller group consisting of 125 independent operators with staff. These companies employ people who are paid according to collective bargaining agreements. We still keep a close eye on workload and job satisfaction. It is fair to say that this is better in some places than in others. But we are making every effort to be a social employer. Our people are our most valuable asset, like the parcel deliverer in the street who everyone knows.”

However, he says, the importance of data should not be underestimated: “If you have to deliver between one and two million parcels per day and each delivery van can carry 200 parcels, then you need prediction models. So data is crucial for us. The parcel is scanned at every step in the process, so we know where it is, and we compare historical data where possible. The better we are at data-driven management and forecasting, the greater our company’s success. Last year, we hired 150 IT professionals. Fortunately, people are enthusiastic about working for us. They see that PostNL is working towards the future, towards greater sustainability, and that it is making a contribution to the Netherlands. Young people in particular are keen to work at companies with such a mission.”

“The better we are at data-driven management and forecasting, the greater our company’s success.”

About the interviewee

Rogier Havelaar graduated from Tilburg University in 2009 as a Master of Science in Organizational Sciences, among other things, and received his Master of Arts degree in Philosophy from Vrije Universiteit Amsterdam in 2011. He has worked at PostNL for more than 11 years now, in the positions of Smart Society Program Manager, Director of City Logistics and Parcels Sustainability & Logistics Manager.

This interview is held by Arjan Gras, interviewer.

Don't miss out on the next insights.

Sign up to our mailing list and be the first to receive our newest insights and digital magazine in your mailbox.