This customer is a global organization in transport and Logistics, in this case: contract logistics. They are one of the leading global logistics services providers.

Their contract logistics business segment manages more than 10 million square meters of logistics space worldwide.

Logistics Optimization for Global Logistics Provider

The Contract Logistics division was looking for an optimization solution that would allow it to plan and schedule daily routes for several of its warehouses across Germany. As part of its planning and scheduling operations, it needed to consider – in addition to tight delivery time slots – requirements for vehicle facilities, warehouse capacity, and the planning horizons set.

Essentially, the process between storage and transportation had to be synchronized and coordinated using a pull strategy, which means that commissioning (order picking) is determined by the transportation plan. In order to ensure that materials handling, and loading occur are efficiently timed, the Transportation Planning division has only a very limited time window available to create an optimized transportation plan.

This sharp reduction in lead times, the creation of a continuous information flow without system disruption, and the option for expansion to accommodate future new business represented the biggest challenges.

New Supply-Chain Planning System for Contract Logistics Provider

ORTEC managed to persuade this customer mainly through its extensive expertise, its in-depth knowledge of the industry, and the individual configurability of its optimization solutions. References to similar projects at the preliminary stage showed the customer the potential savings that they could achieve.

In addition, the reorganization of all the company’s processes through ORTEC’s solutions led to further benefits, including reduced media disruptions and correspondingly lower error rates.

Synchronization of Warehouse and Transportation

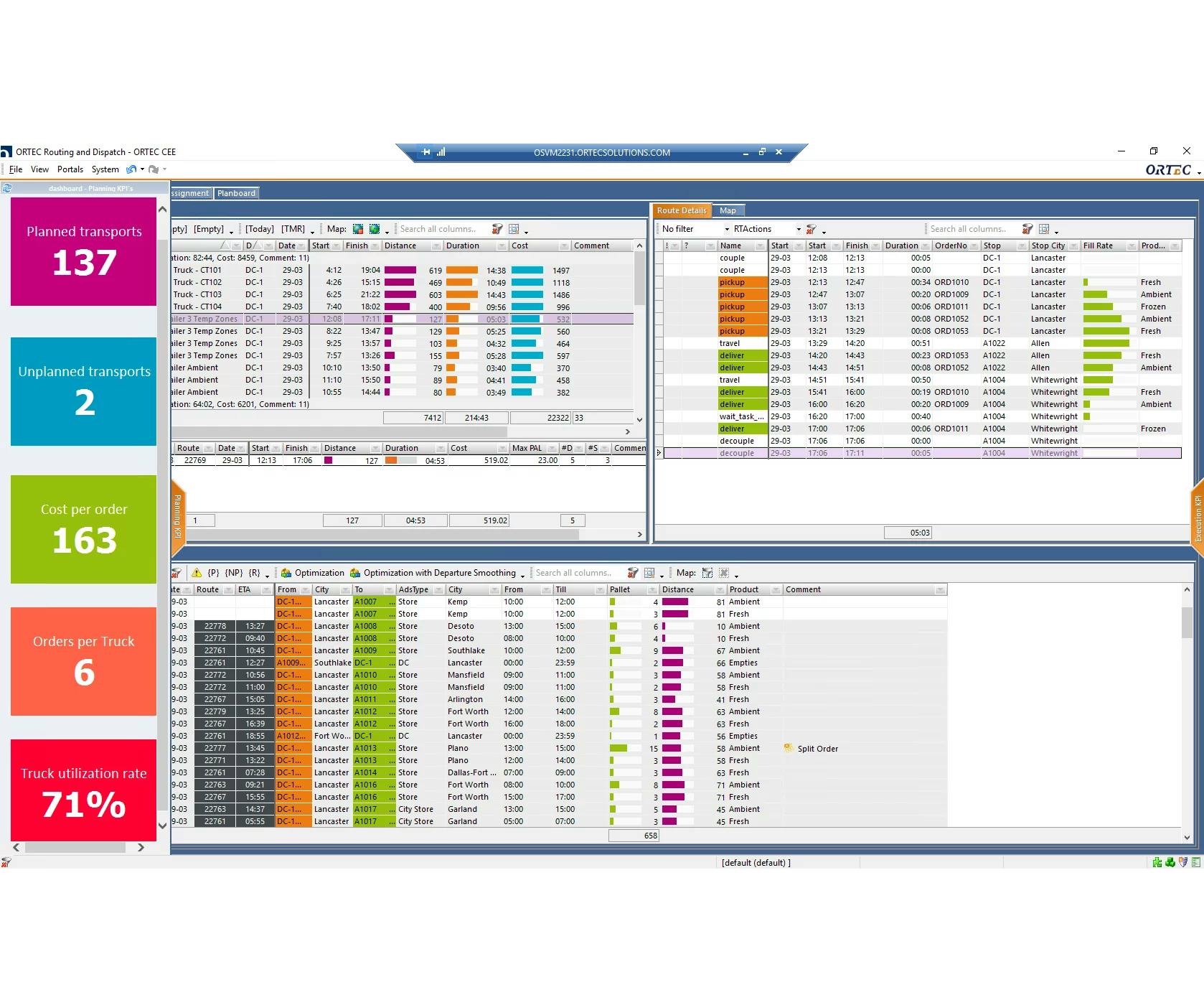

The implementation of ORTEC Routing and Dispatch is used to manage the company’s day-to-day transportation planning operations.

In addition, the logistics company uses ORTEC’s Load Building solution at one of its other sites, while the solution also supports pallet stacking for subsequent transportation planning.

Two of ORTEC’s logistics optimization solutions are therefore currently used to achieve planning results that are communicated to several systems within the IT landscape.

A strategic solution created by ORTEC supports both network planning and scheduling and challenges in tender management, including for other locations and users.

The Benefits of Data-Driven Optimization

- Efficiency: The implementation of a Single Point of Contact (SPOC) has reduced the previous five individual solutions to a single software solution, thereby significantly reducing complexity while at the same time increasing accountability.

- Reduction: Planning expenses for dispatchers could be substantially reduced compared to the previous solution. The extremely time-critical window from 8:00 a.m. to 12:00 p.m. no longer needs to be fully utilized.

- Clear and well-organized: All processes are optimized and based on an integrated approach, resulting in significant cost savings. Dispatchers already see all costs incurred and revenues generated during the planning and scheduling process.

- Reliability: Realistic planning made it possible to fulfill the time windows as agreed, which has a positive impact on the Service Level Agreements signed.

- Customized: The specific vehicle fleet of the Contract Logistics divisions is reflected in the system setup.

- Integration: The ORTEC solution was seamlessly integrated into the customer’s Warehouse Management System using standard interfaces.

- More environmentally friendly: The planning results lead to a reduction in the number of kilometers traveled, as well as to increased utilization of the vehicles, which reduces environmental impact.

“The biggest challenge was to achieve realistic transportation planning results within the scheduling time window, where time is of the essence”

Distribution Manager.

In Conclusion

The integrated process analysis and optimization ensured that the complex implementation of the project could be successfully completed. The aspired system integration was fully successful – combined with reduced complexity and increased accountability.

“We were able to gradually integrate individual customers of the logistics services provider, based on the requirements, and transfer the data to the project structure and our work packages”.

Jürgen Sorg, ORTEC Project Manager