Load Optimization Scenarios

Carton, pallet and vehicle optimization can add value to many areas in a business. Below are example scenarios where companies have used these technologies to reduce costs and gain a competitive edge. When looking at optimization, consider that where it is implemented can support subsequent processes.

Intercompany, Demand-Based and FTL Planning

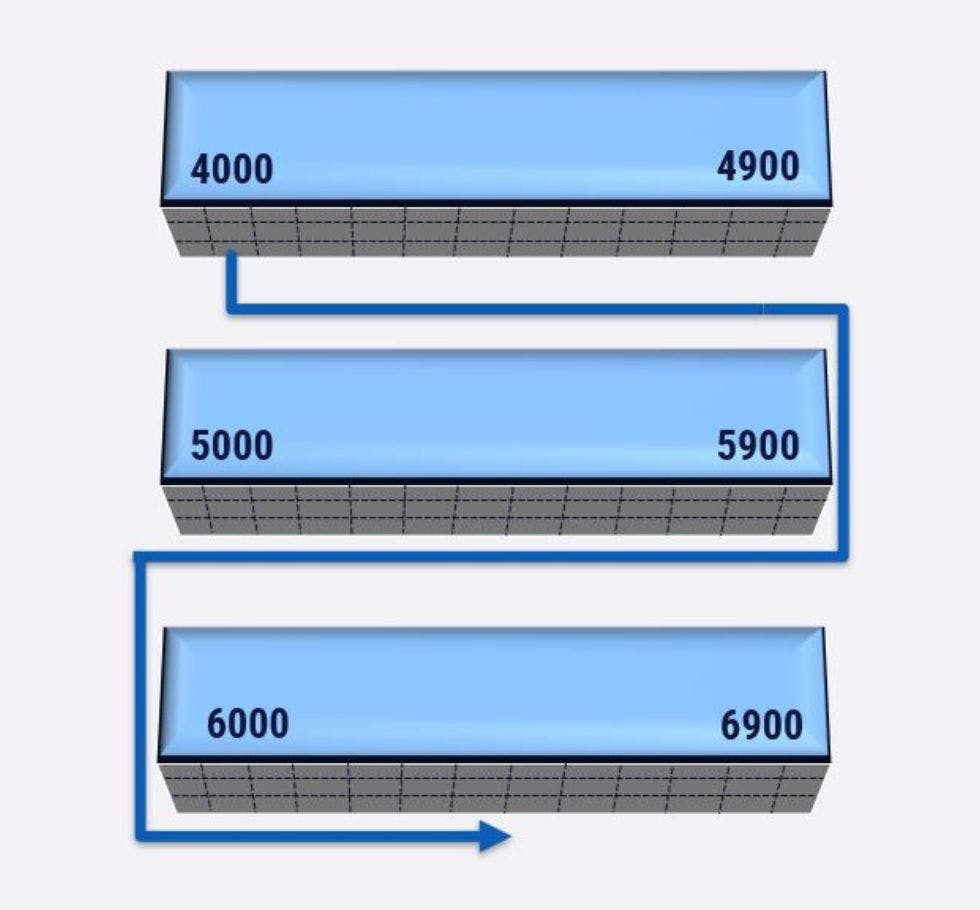

Optimizing truck utilization upstream, before order creation can bring substantial savings. When you are not limited to planning based on predefined orders a high degree of utilization can be achieved. Consider using an optimizer to maximize transports based on demand, need-by-date, VMI or other priorities.

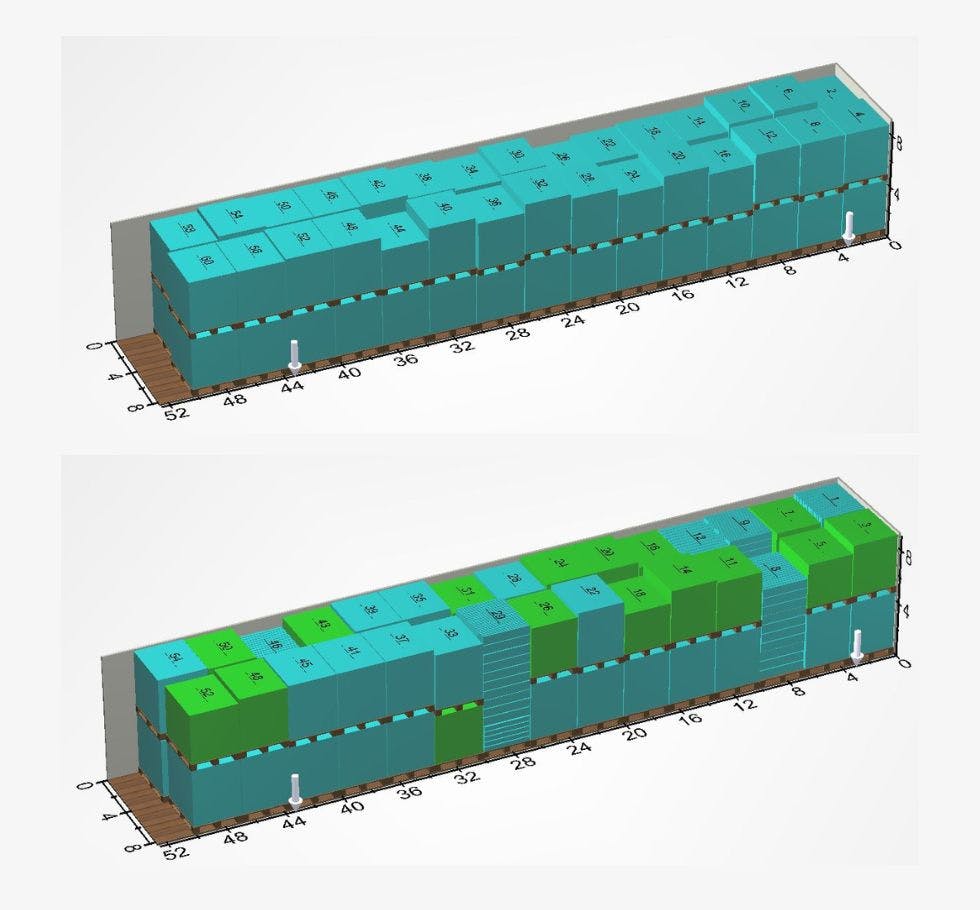

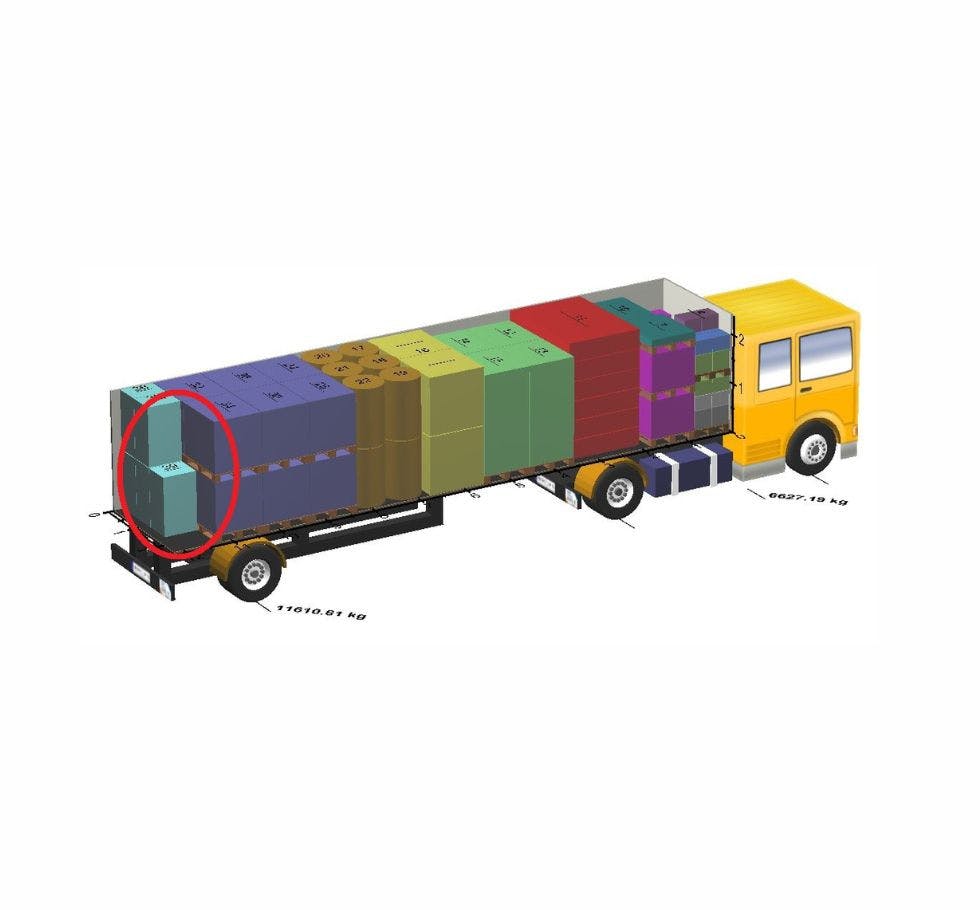

In the following example, the optimization algorithm was given a list of products that needed to be shipped over the course of a few days with varying priorities. The challenge for this company is that they have a high variance in weight through a broad product range. Think about heavy peanut butter and canned soups being loaded together with pasta and cereals. The algorithm can balance these factors achieving high volume and weight utilization, across multiple transports and assuring that the transports are within legal limits.

In the graphic, all priority 1 items (turquoise) are loaded in the first transport and priority 1 + 2 items (green) are loaded in the second transport. The first transport has a 98.2% weight utilization and 87.5 volume utilization. The second transport has a 99.4% weight utilization and a 90.3% volume utilization! The result was calculated in just a few seconds.

Image: Colorized by need-by-date – Balanced weight and volume across multiple transports. Lower, priory items (green) mixed in after all "must haves."

Order Management

Implementing pallet and load optimization at order entry can help businesses in several areas. First, it enables sales teams and customers to take decisions on order quantities based on accurate utilization. Truck and pallet utilization can be visualized to provide a clear view of capacity. Shipping quantity can be decreased if a transport is overloaded or increased to maximize utilization. ORTEC’s loading algorithm can even suggest additional product quantities to fill remaining space/weight on a transport.

This can lead to improved customer service and improved efficiencies in subsequent processes.

Additionally, having a clear view on transportation requirements at order entry can be used to support capacity planning for transportation, transportation procurement, and warehouse processes.

Image: 3 additional products can be loaded on trailer with no axel violations

Transportation Planning

Consolidation of multiple deliveries on a transport accurately can be a difficult task. There are many goal conflicts that need to be considered to find the most optimal solution. Can all products be stacked on one another? What about individual customer requirements? Do certain products need to be held together or separated on a load? How about the delivery sequence in multi-stop trips? Is the optimal truck size and type being used for the load and customer? Will the truck or axles be overloaded? Can more products fit on the truck? Are the products staged efficiently for loading?

A pallet and load optimization solution can automate this planning process taking into account business rules and best practices from your seasoned professionals.

Image: Example Goal Conflicts in transportation planning.

Warehouse

Using an optimizer for pallet and load optimization provides a sustainable way to produce optimal results in the Warehouse. We’ve been on warehouse walk-throughs before. In non-automated warehouses we are introduced to a veteran picker who shuffles through aisles placing products on pallets like a Tetris game. Forklift drivers zip around placing pallets in a pre-stage area before reorganizing products for proper loading. In most cases however the picking and loading quality is not consistent and quality can vary from employee to employee.

With an optimizer the planning process can be automated so that there are clear plans for pickers, forklift drivers and AWSs. Products can be staged correctly the first time, leading to fewer product movements. New and seasonal hires will have tools to build pallets and load trucks optimally based on predefined business rules.

Pallet and Loading optimizers can automate the planning process to produce optimal, standardized and sustainable results.

Picking

How to pick optimized pallets? Using an optimal pick sequence of course... For several customers, we have developed strategies to build optimal pallets based on their unique warehouse attributes. This includes things like sending layer build sequencing to automated layer pickers and building pallets in an optimal way based on the warehouse layout.

As mentioned in the previous section, having clear pallet and loading instructions for warehouse pickers and forklift drivers enables efficiencies in the warehouse for picking, staging and loading as well as standardization that is difficult to achieve without optimizers.

Carton Optimization

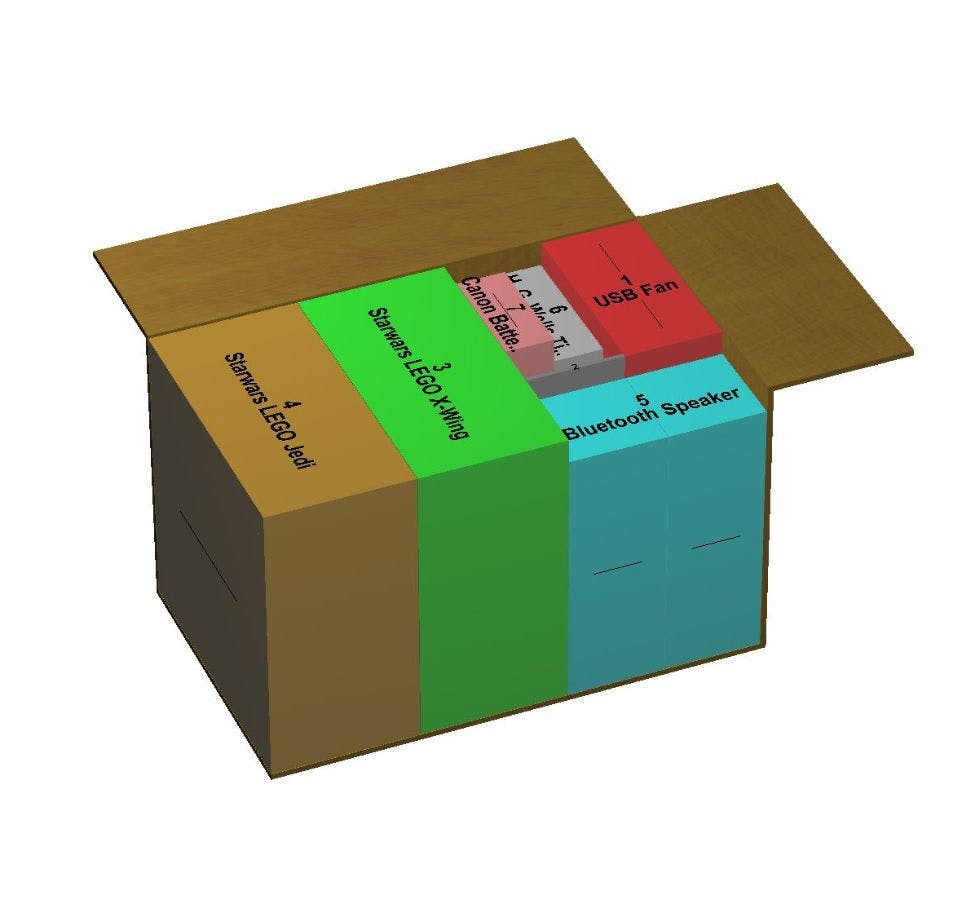

With more and more products being shipped with paper cartons, carton optimization has become a very important tool in reducing shipping costs as well as environmental impact caused by increased paper usage.

Given a set of different products, ORTEC’s 3D carton optimizer can select the most optimal size carton based on all available carton sizes. This capability can be implemented so that the selection is dynamic, with no user interaction. This will streamline the carton selection process and ensure that the most optimal carton is used for any shipment.

Image: Optimal shipping carton selection with 3D optimizer

Reimagine Distribution

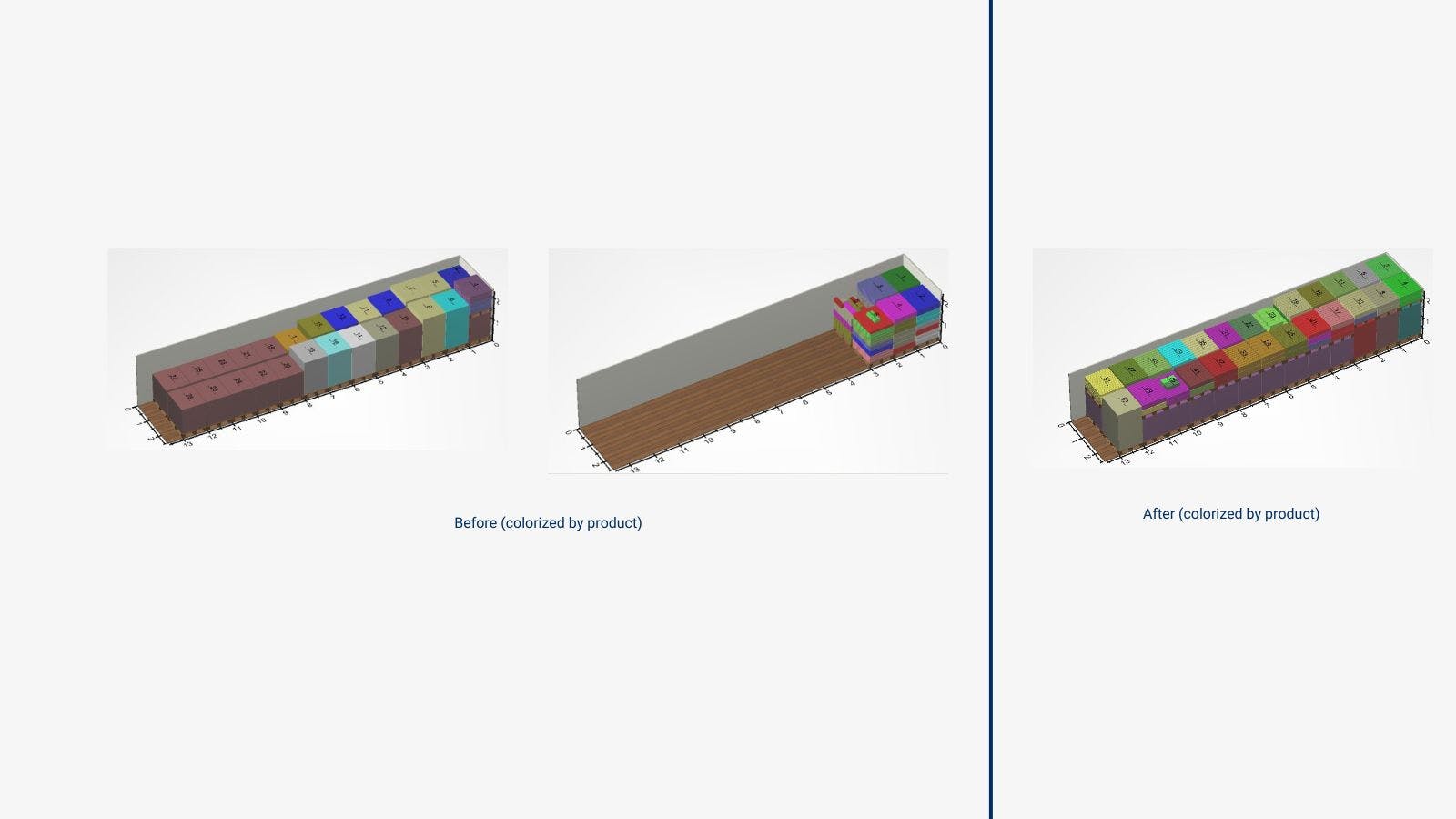

Companies use the power of our algorithms to achieve results that were difficult to imagine or were not able to be realized consistently in the past. We have numerous examples of how companies save substantially by using our algorithms in new ways. One example is the following case with 2 transports (before). In a new scenario, the company allowed the pallet algorithm to consider the trailer dimensions when optimizing pick pallets. The result is that pick pallets can be sized in an optimal way to fit into 1 transport (after optimization).

Image below: Before (colorized by product) & after (colorized by product).

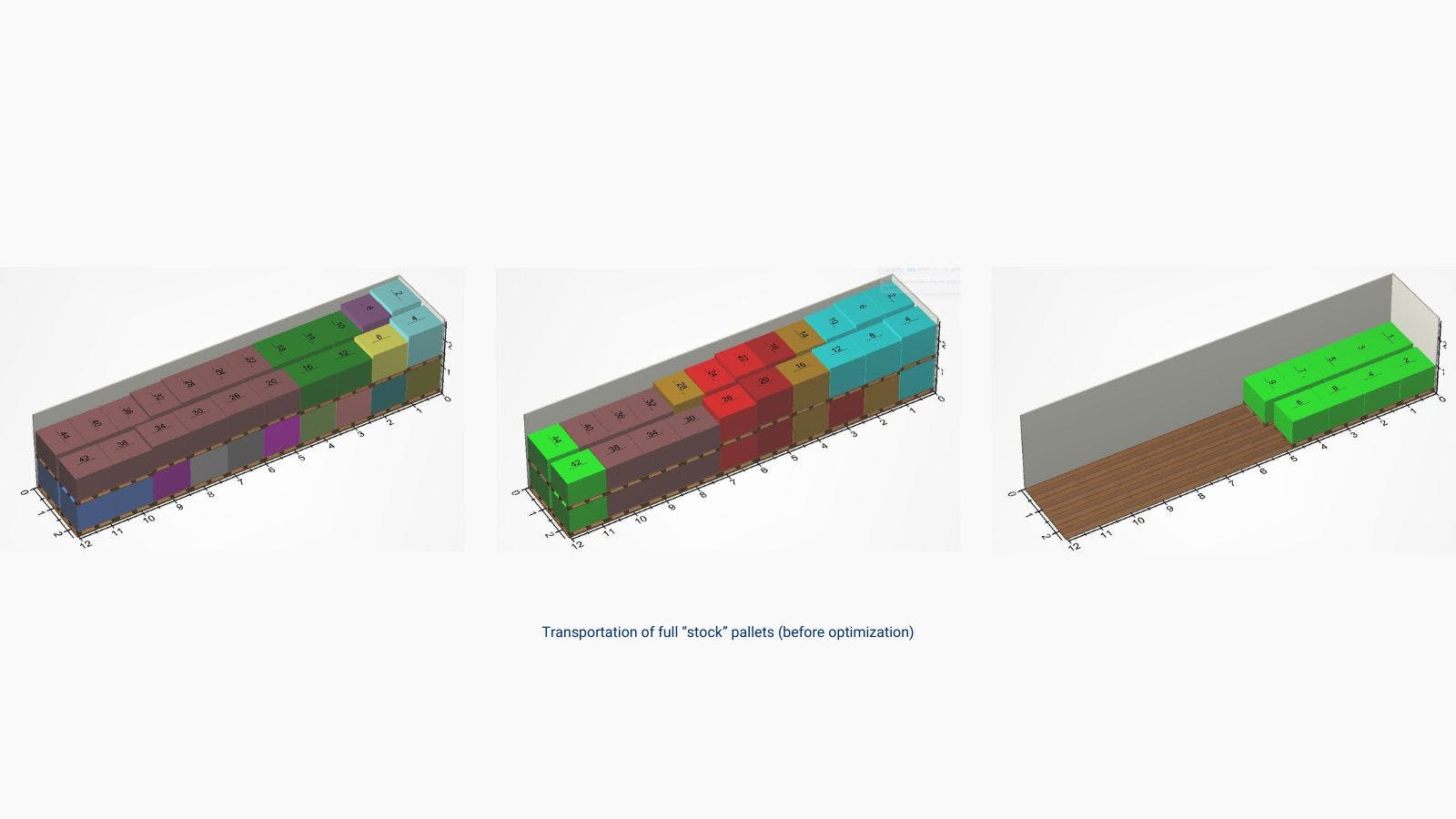

A similar approach is used at another company. Instead of pick pallets however, the company allows the algorithm to depalletize full stock pallets (production pallets) so that certain products can be “loose loaded” on top of other pallets in their transports.

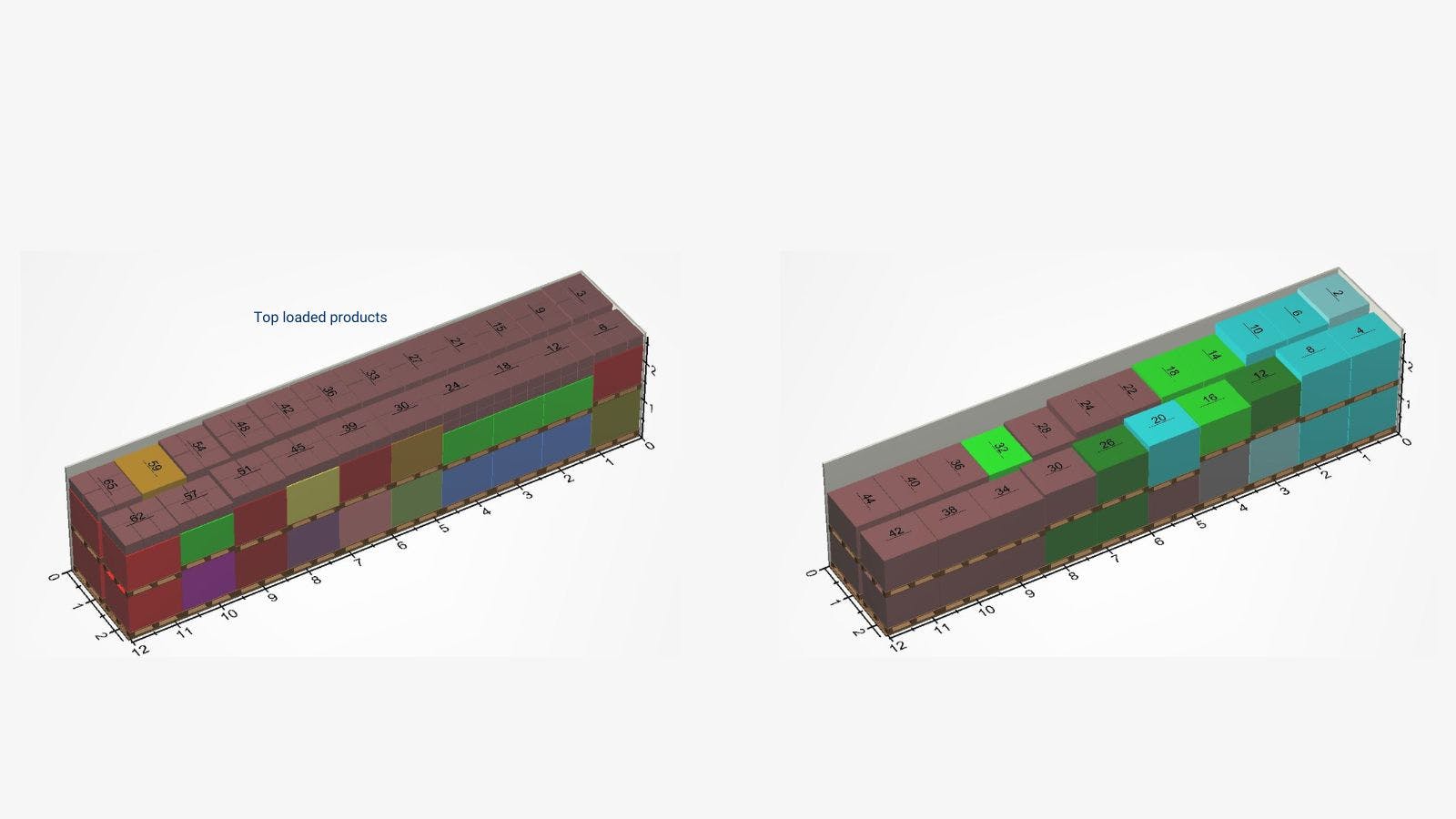

The first graphic illustrates the necessity of three transports without employing the top-loading technique. However, in the second graphic, the optimizer successfully condensed the same quantity of products into two transports. This was achieved by strategically depalletizing a minimal number of pallets and efficiently loading the products on top of the existing load.

Image below:Transportation of full “stock” pallets (before optimization)

These are only some example of how optimizers have been implemented at companies. There are many more. Do you see other ways that a pallet and loading solution can add value to a business?

Image below: Top loaded products: Optimizer depalletizes some full “stock” pallets so products can be top-loaded. The result is that all products can be loaded into 2 transports.

General Benefits of Pallet and Load Optimization Technologies

The usage of ORTEC solutions can have many positive impacts on your business. This section contains some of the potential benefits that can be achieved using mathematic algorithms to optimize in your cartonization, pallet building and load planning processes.

Cost Reduction

- Decrease in the number of transports

- Optimization for lowest cost transports

- Increase in pallet utilization/reduction in number of pallets

- Increase in transport utilization

- Decrease in fuel costs

- Decrease in warehouse man hours for pallet and load planning

- Reduce planning time/implement later order cutoff times.

- Minimization of loading times

- Decrease in picking and staging time in warehouse/DC’s

- Organization of pallets to support the correct picking processes in the warehouse; E.g. layer line pallets vs. picked pallets

- Enablement of further growth with regard to logistics

- Strategic decisions on logistics can be supported by comparing different scenarios

- Reduction of administration processes

- Increase in driver efficiency

- Improve warehouse efficiency

- Streamlining of planning tasks can lead to better utilization of planning resources

Reporting

- Detailed utilization information (pallet, vehicle, etc.) can help businesses analyze areas for improvement.

Quality

- Standardization of palletizing and loading

- Creates a consistent and repeatable loading process

- Reduction in the learning curve for new & temporary staff with pallet/load building

- Decrease in damage goods due to improper stacking and loading issues

- Enable new possibilities for strategic usage of the staging area

- Enable new ideas for innovations for planning

- Increased transparency in the execution (supply) chain

- Optimal planning of resources such as personnel and equipment

Service

- Less pallets for the customer to receive & handle

- Enable ability to automate pallet builds to customer specific specifications – Customer specific pallet types, heights and consolidation rules.

- A more streamlined process for providing the container breakdown for distribution

- Availability of KPI's for measuring optimization, to highlight potential savings

Sustainability

- Reduction in the carbon footprint due to the reduction of transports

- Reduction in wooden / plastic pallets

Safety

- Axle weight and center of gravity calculation leads to safer transports

- Business rules implemented for pallet/loading building leads to safer more stable loads

- Overloading of Trucks can be eliminated or reduced

- Consideration for hazardous goods and relevant loading restrictions

Optimizing truck utilization upstream, before order creation, can bring substantial savings. When you are not limited to planning based on predefined orders, a high degree of utilization can be achieved.

Summary

In summary, optimization technologies offer a wide array of benefits that can revolutionize logistical processes, and many leading companies are leveraging these advantages to gain a competitive edge.

- Cost Reduction: Streamlining transports and maximizing pallet utilization directly contribute to reduced operational expenses.

- Reporting: The creation of detailed data points can be used to gain insights into areas for improvement, enhancing decision-making processes.

- Quality: Implementing standardized palletizing and loading procedures elevates operational consistency.

- Service: Automating palletizing and loading translates into consistency that can lead to a more satisfying experience for customers.

- Sustainability: By minimizing transport requirements, optimization solutions contribute to a lower carbon footprint, aligning with environmental goals.

- Safety: Accurate calculations ensure safer transportation practices, mitigating risks associated with logistical operations.

The scenarios mentioned in this article highlight some ways optimization can generate value, and we encourage you to envision these capabilities within your own logistical frameworks. Considering the significant benefits optimization offers, it's worth exploring how these solutions could positively impact your business.

Please reach out to us for a deeper exploration of how our cutting-edge optimization solutions can transform your business.

Download the E-Guide

Download this article as an ORTEC E-Guide - Carton Pallet and Load optimization

Excellent Read

The transformative impact of ORTEC's pallet and load optimization technologies on your business. Streamline warehousing, reduce costs, improve sustainability. Download this ORTEC E-Guide about Carton Pallet and Load optimization

Jason Lafata, Director of Value Realization and Senior Account Manager at ORTEC.

About Jason Lafata

"As the Director of Value Realization and Senior Account Manager at ORTEC, Jason Lafata brings over 19 years of dedicated expertise in leveraging mathematics to unlock value in the logistics domain. With a keen focus on helping companies achieve operational excellence, Jason's strategic approach revolves around reducing costs, improving customer service, employee satisfaction, and enhancing overall efficiency. His role involves spearheading projects that not only contribute to the financial success of organizations but also generate positive environmental impact through innovative solutions. Jason's commitment to bridging the gap between cost efficiency and sustainability positions him as a key influencer in the intersection of logistics, technology, and environmental responsibility."

Get in touch!

Please contact ORTEC's experts to further discuss how we can transform your business logistics with our state-of-the-art optimization solutions. Request a demo today.