The COVID pandemic disrupted all the global supply chains we had grown so accustomed to, while current geopolitical developments (the war in Ukraine, changing relations with Russia and China) and subsequent changes in terms of security of supply of gas, grain and other products are leaving their mark on the economy and society as a whole. And the transition to renewable energy is still in full swing.

Unstable energy market

Lucia van Geuns, energy advisor at The Hague Center for Strategic Studies, expects the energy market to remain unstable for the foreseeable future. While the West has coped relatively well with the cutoff of Russian gas, the switch to green energy requires strategic resources for which we are now largely dependent on China. And our future relationship with China is by no means certain. All the while, the energy needs of the industrialized world are only increasing, which does not make the transition any easier. Van Geuns does, however, draw hope from the increasing awareness worldwide: “The US is on track for 2050 and Europe has followed suit with the Green Deal. It will take China and India a little longer to reach low carb/net zero, but they will get there in the end.”

Lucia van Geuns, Energy Advisor at The Hague Center for Strategic Studies

"The new energy system will rely heavily on IT"

According to Van Geuns, the challenge lies in moving away from “a completely fossil-dominated system” while the new system has yet to be built. She expects the new system to rely heavily on IT: “You need IT to manage all those North Sea wind farms. All the infrastructure has been computerized and is controlled with the help of data and math.”

Data analysis and AI set to play major role

How important data analysis and AI will be for the green transition is shown by Dutch railway company NS. Mea Westerbeek, Manager of Sustainable Business at NS, stresses that sustainability is paramount to NS because the transport company consumes 1.5% of all Dutch electricity and is therefore keen to set a good example: “We started buying electricity from wind farms in the Netherlands and neighboring countries in 2015 and switched all our trains to wind energy in 2017.”

NS saves energy by buying and recycling efficient trains, but also by planning smarter and preparing itself to make last-minute changes. Bart van Zaalen, head of Digitalization of Operations at NS, confirms that rolling stock deployment plans always change on the day itself. “When you are forced to make ad-hoc modifications, you want to be able to set clear priorities to maximize the efficiency of the rolling stock you do deploy and optimize energy consumption. “That logistics puzzle has become increasingly complex and challenging in recent decades.”

"The logistics puzzle has become increasingly complex and challenging in recent decades."

Sustainability and economy gains

Unsurprisingly, NS is increasingly embracing techniques such as advanced analytics and operations research to avoid over-utilizing and under-utilizing capacity. This is reflected in the timetable, which is increasingly geared to energy-efficient operations. According to Gerben Scheepmaker, NS Business Consultant, there is “considerable potential there. If a driver is traveling 140 kilometers per hour on a double-decker and he turns off traction, the train will coast for 20 kilometers and still reaches a speed of 80 kilometers per hour. The savings are obvious.” Drivers today receive support from a Driver Advisory System, which tells them when they can start coasting whilst still arriving on time and results in savings that Scheepmaker says amount to about 5% of NS' traction energy consumption. “We’re talking millions of euros.”

To achieve its long-term sustainability goals, NS has to deal with another factor that can spawn uncertainty: all the other parties involved in train traffic. The government, ProRail, data and digital tool suppliers, passengers: they all play a role in the chain.

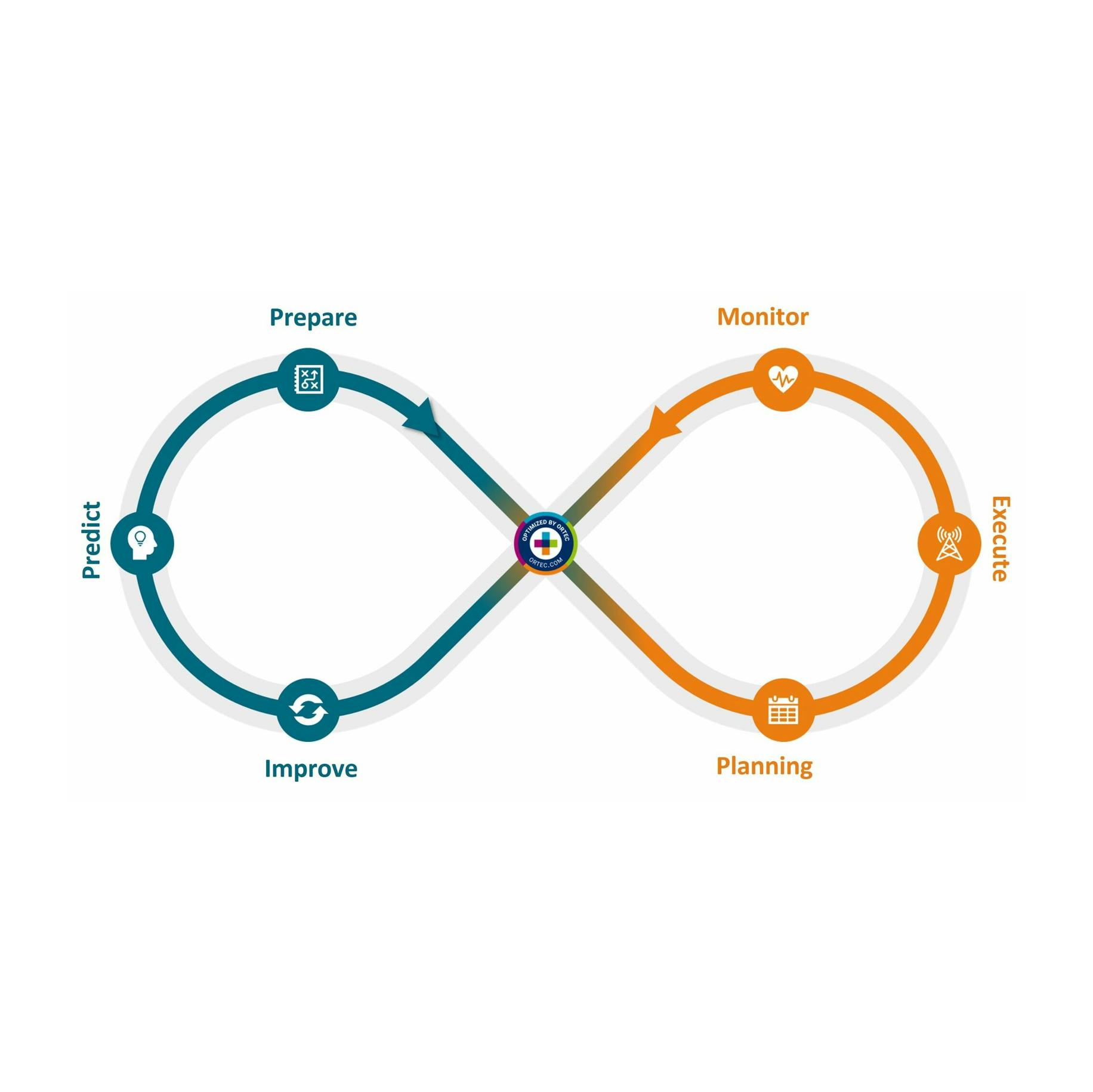

The Learning Loop: constantly prepared for an uncertain future

The Learning Loop was developed to help companies respond faster to changes in the marketplace, and continuously adapt plans to new circumstances. The Loop consists of six parts:

- Predict: Given market conditions, external factors, and realizations, predict workload and availability for the coming period.

- Prepare: With predicted workload and improved parameters, simulate what-if business scenarios to prepare for upcoming operations.

- Plan: Based on one scenario, determine the schedule, work packages, and resource assignment for daily operations.

- Execute: Execute the planning for the day by communicating with resources, reacting to disturbances, finding solutions, and getting the job done.

- Monitor: Evaluate and alert on operational KPIs and their real-time effect on performance, sustainability and customer and employee happiness.

- Improve: Determine improvements based on operational results, KPIs, and realizations by learning and fine-tuning planning parameters.

How each part is fleshed out depends on the needs of the companies and supply chains to which it is applied. Planning can include timeslot booking, for example, as well as route planning and yield management.

Ideally, the Learning Loop should be an ongoing process that allows companies to make maximum impact.

Plan B for supply chains

Streamlining supply chains is a specialty of Gerrit Timmer, co-founder and Chief Science Officer of ORTEC. He notes that as many as 73% of all companies experienced problems in their supply chains during the corona pandemic, which he attributes to the complex dependencies in a global economy. While companies used to keep many of the products, materials and parts they need in stock, they have now switched to a just-in-time system that is - admittedly - highly efficient, but also more susceptible to unexpected disruptions.

Timmer therefore recommends companies to have a "plan B" ready in case things unexpectedly go wrong: "You want to figure out which parts of the global transportation path are most vulnerable, in order to prepare for bottlenecks and disruptions. You have to anticipate, and calculate the repercussions of possible scenarios in advance, so you have an understanding of how susceptible you are to particular events." According to Timmer, drawing up scenarios is a good place to start. “When you need to respond to real-world events, having the processes, organisation and skills you need in place is a massive help.”

Gerrit Timmer, Co-owner and Chief Science Officer at ORTEC

"You have to anticipate, and calculate the repercussions of possible scenarios in advance, so you have an understanding of how susceptible you are to particular events."

Tight labor market

Digital tools for route planning and optimization can help smooth out disrupted supply chains quickly, but a shortage of human resources remains the biggest risk factor. The current labor market is incredibly tight, which can make it difficult to find qualified staff. "The right workforce scheduling tool provides insight into the work to be done and the number of people available to do it. If you have that knowledge, you can create a schedule with the goal of getting that work done as effectively as possible, while also optimizing job satisfaction."

According to Timmer, staff shortages will remain a factor for some time, "because demand is set to explode, especially for certain skills in AI, data science and applied mathematics. We need to think carefully about what type of skills we need in the future. What can your organization do to bring in the skills it needs?”

Using algorithms

Few people will argue that digital skills, data analytics and algorithms are not increasingly influencing everyone's daily lives. According to Goos Kant, Managing Partner at ORTEC and professor in Logistics Optimization, how they are used is key. The UN World Food Programme is successfully using algorithms to prepare for famines in the future. Algorithms help make logistics operations more efficient and can even determine the optimal nutritional value of meals for refugees.

Moreover, the police can apply algorithms to identify the neighborhoods with the most crime and concentrate officer deployment there. This, however, comes with a catch, because these algorithms can also reinforce existing biases. Less attention is paid to "safer" neighborhoods, so more crime escapes attention there, while the "more unsafe" neighborhoods only appear to be getting worse, purely because more police officers are stationed there.

Goos Kant, Managing Partner at ORTEC and Professor of Logistics Optimization

"There is no Holy Grail of fairness, and what we perceive as ‘fair’ changes over time. Choices are often subjective, but algorithms can make them more objective."

Innovation in times of uncertainty

Not all innovation is effective. In uncertain times, however, innovation is a smart move, says Suzanne Thomasson, member of ORTEC’s Innovation Practice Team. Uncertainty shines a spotlight on existing problems and encourages the people involved to develop and accept solutions more quickly. As uncertainty seems to be becoming the new normal, innovation seems to offer the surest way out.

Suzanne Thomasson, Analytics Consultant and member of ORTEC’s Innovation Practice Team

"In uncertain times, innovation is a smart move."

Download your magazine

This article is an Executive Summary of the 4th issue of our magazine Data and AI in the Boardroom. Get your copy now.

We've asked leading figures in different sectors about how their organizations plan for the predictable and prepare for the unpredictable, and how using data and analytics in innovative ways help them to deal with uncertainty.