Streamline Your Logistics Chain with Optimized Shipments

As a manufacturer, you need to deliver all types of products (SKUs) with their own delivery and demand patterns to your customers, such as retailers or other manufacturers. How do you determine the right amount of each product to deliver at a specific moment in time, maximizing load utilization and minimizing handling time, while also meeting requirements like transport restrictions, demand, inventory levels, and service agreements? Add to that the added complexity of customer requirements, warehouse picking and loading strategies.

In this article, we'll explore the opportunities to create shipments with high load fill through order optimization and the significant benefits it brings. By doing so, you can revolutionize your shipping policy to your customers. Although optimizing on demand level may not be feasible for all your customers, you can start by implementing it internally for inter-company replenishments.

Written by article by Goos Kant, Managing Partner at ORTEC and Professor of Logistic Optimization.

Want to deepen your understanding of advanced load building and order optimization? Explore our E-Guide "Carton, Pallet, and Load Optimization: Business Scenarios and Benefits", and streamline your warehousing, reduce costs and improve sustainability.

Perfectly loaded shipments

The logistics chain in the manufacturing industry faces many challenges, including uncertain and volatile demand, significant transportation costs, and scarce resources. Thus, there's a growing emphasis on maximizing load utilization of shipments to reduce the carbon footprint. These perfectly loaded shipments require minimal handling while maximizing load utilization.

Creating shipments with multiple products to maximize load utilization is a complex task. Products have their own frequency, min/max stock levels, and demand patterns. Determining whether they fit into a trailer (or other loading unit) is complicated due to stackability rules, axle weight limitations, and various picking and loading strategies. Additionally, transportation efficiency may result in longer loading or unloading times in the warehouse. However, there may also be some flexibility, such as flexible delivery days for certain products or the ability to mix them with others. We see these opportunities in the automotive supply chain.

Example of Opportunity

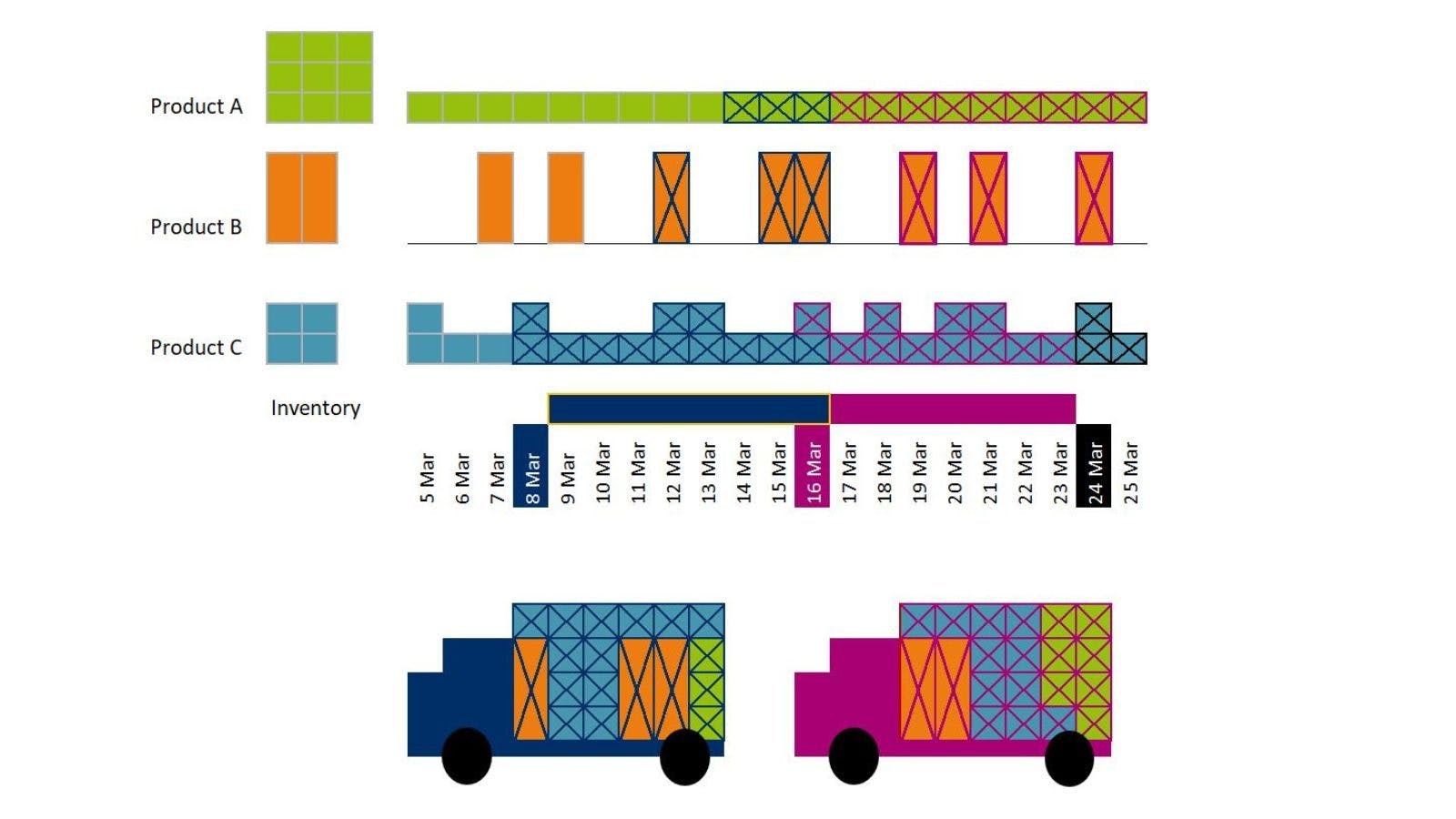

Consider a manufacturer with three products (A, B, and C) optimizing deliveries from a vendor-managed inventory perspective (the same example can be applied to inter-company and inbound deliveries). The demand for the upcoming period is shown in Picture 1. On March 5th, there's an inventory of 9 units of product A, 2 units of product B, and 4 units of product C. We follow these steps:

- Define the latest possible date for the next delivery: this is March 8th when product C is out of stock (for products B and A, this is March 10th and 14th, respectively).

- Align all coverage dates: this means covering 1 unit of product B and 9 units of product C until March 14th (refer to Picture 1).

- Fill the truck up to the targeted trucking filling ratio while covering the longest period for all references: in this example, this is on March 15th (refer to Picture 1).

Picture 1: Example when to deliver full truck loads to meet all requirements

This results in a full truckload delivering latest on March 8th and covering all demand until March 15th. The process is repeated for the delivery latest on March 16th, covering all demand until March 23rd with a full truckload (refer to Picture 1).

The optimization challenge becomes how to minimize the number of deliveries while maximizing the covering period and load utilization while mixing multiple product types.

Extensions: ‘creating the right puzzle’ before ‘solving the puzzle’

In the example, we explained how to optimize shipments and delivery schedules given various products, each with their own demand, rules, and restrictions. We refer to this optimization challenge as 'creating the right puzzle' compared to simply optimizing loading utilization for a given delivery schedule, which we call 'solving the puzzle.' Based on our experience, the value and benefits of 'creating the right puzzle' can be twice as much. This approach can be applied, at minimum, to intercompany replenishment orders, but there are also opportunities to arrange it for inbound and/or outbound deliveries.

There are various extensions that can be made to the above example, including: priority rules that determine which additional products to include when there is space available. This may depend on factors such as product availability and inventory, as well as relationships between products. In the case of large orders, it may be possible to split the orders into multiple loads, combine heavy and light orders, implement vendor-managed inventory, and/or schedule deliveries at specific times (such as the end of the month).

Savings and benefits

To emphasize the impact of this decision further, let's consider a customer on vendor-managed inventory that currently requires 50 truckloads per week to receive 1.6 million pounds of your products. That's 10 loads per day, with an average of 32,000 pounds per load. However, by improving the planning during order acquisition and demand creation, we have seen a 10% improvement in load utilization at the time of shipment execution. This means that the same total volume can be transported in 45 truckloads per week instead of 50, with an average of 36,000 pounds per load instead of 32,000. In terms of hard dollar savings, considering a simple cost of $1,200 per trailer, this translates to a savings of $6,000 for this single customer per week. That's a savings of $312,000 for this single customer in a year.

Additionally, moving less air results in less risk of damage. By creating transparency in the loading process and informing the receiver of the details and expected arrival time, the receiver can better prepare their part of the supply chain. Moreover, the optimizer's ability to apply business rules to create 'receiver-friendly' loads may reduce the handling time for the receiver.

Henkel Customer Case

Founded in 1876, Henkel operates in three business areas: Adhesive Technologies, Beauty Care, and Laundry & Home Care. The company employs more than 52,000 people globally and is committed to creating sustainable value. Corporate sustainability is a core value for Henkel, and they require their suppliers to be as responsible as they are. Henkel saw ORTEC's Ecovadis Gold Status as an added benefit when choosing us as their technology vendor.

ORTEC’s solution enables Henkel to digitize its planning process for internal (stock transfer) orders. Sophisticated algorithms allow planners to focus on exception handling, while most logistics flows are planned automatically based on master data, operational data, and business rules. Henkel has seen numerous benefits from ORTEC’s solution, including less time spent on manual tasks by planners, more accurate and timely planning decisions, and reduced transport costs through optimized truck loads.

Conclusion

In conclusion, optimizing shipments is key to revolutionizing your shipping policy and maximizing savings in your logistics chain. By streamlining the logistics chain, you can increase load utilization, reduce handling time, and improve the efficiency of your transportation process. By following the example outlined in this insight and incorporating extensions like priority rules and splitting orders, you can take advantage of the many benefits that come with optimized shipments.

At ORTEC, we have extensive experience in logistics optimization, and we can help you apply these concepts to your specific manufacturing needs. Contact us today to learn more about how we can help you streamline your logistics chain and increase the efficiency of your shipping process.

Want to learn more?

At ORTEC, we have extensive experience in logistics optimization, and we can help you apply these concepts to your specific manufacturing needs. Contact us today to learn more.