Optimized route planning based on decentralized scheduling across four sites using ORTEC Route Optimization

Maxit chose to implement ORTEC Routing and Dispatch (ORD), a logistics software solution for transport planning and scheduling and route and resource optimization. ORTEC convinced maxit mainly through its extensive expertise and knowledge of the industry, which it has acquired through similar projects in the construction industry. These credentials made it possible to analyze the potential cost savings during the preliminary stage.

The operational scheduling solution ORD could be seamlessly integrated into the company’s existing IT infrastructure. ORTEC’s experts designed the business case to fully align with the customer’s needs and requirements in terms of workflows, organization, user interfaces and algorithms.

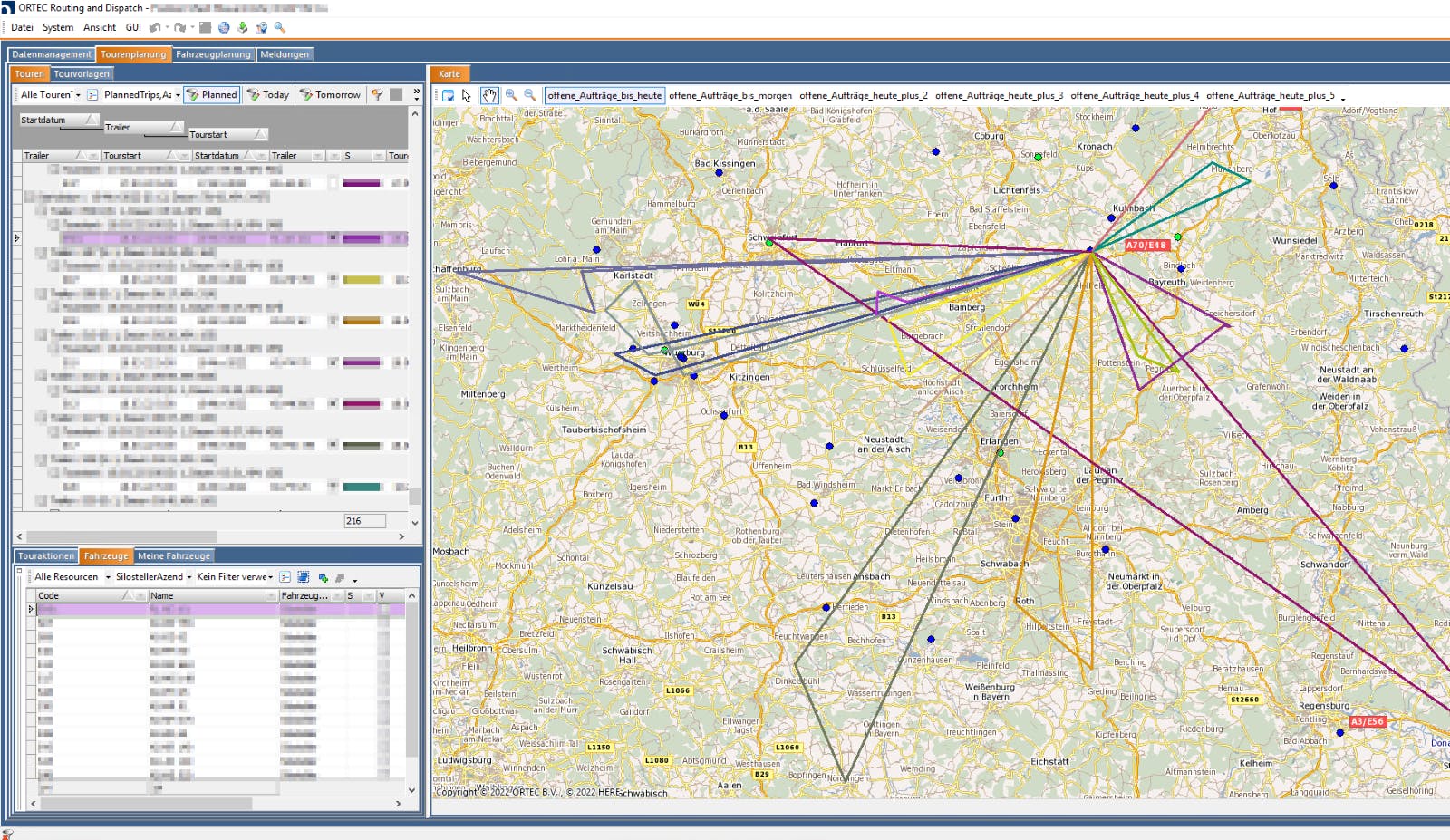

Scheduling will from now be managed at a decentralized level from the company’s four sites. Depending on the type of work environment, users can access data either limited to their geographic area or relevant to their work activities. Since this is a company-wide scheduling platform, schedulers have general access to all data.

Optimized Use for Stronger Logistics Performance

One’s of ORD’s main strengths is its intuitive operability.

Automized processes minimize manual operations In addition to information provision, this includes internal communications and change management.

Scheduling costs and scheduling time can be significantly reduced for schedulers compared with the manual operations previously in place at the company.

A color-coding system is used to separately visualize the worklist and outstanding orders. Scheduling board visualizing vehicle utilization.

Reliable data for picking.

Seamless data exchange between ORD and Maxsoft. Duplicate entries of orders are no longer made

Higher productivity thanks to automated route planning

Implementing ORTEC’s ORD solution has helped maxit achieve its self-defined goals. The previously complex manual processes and procedures could be significantly reduced and optimized, while simplified and automated processes have improved productivity.

In conclusion

Well-organized and regular exchange will enable the company to continue to fully utilize optimization potential in the future. The success of the project is due mainly to ORTEC’s high level of timetable flexibility during implementation in the slower months of the year (when orders are low) and to the rapid integration and high level of adoption by the scheduling teams.

"The excellent collaboration between everyone involved in the project made it possible to fully incorporate the industry-specific and customer-specific requirements into ORD. The hands-on implementation contributed to the high level of adoption of the application."

Jürgen Sorg, ORTEC Project Manager

Want to know more?

Find out how to save cost and optimizate logistics with ORTEC's Routing and Dispatch solutions