Supply Chains Need to Adapt

Every supply chain has a way of working that evolves throughout the years. At some point, you may find that your organization's goals and portfolio have shifted, but that the evolution of the way of working has not been in line with the shift of the business goals.

Despite these changes, departments tend to maintain a functional focus. The consequence is that the supply chain performance is under pressure and performance measures do not reach their target levels. Modern supply chains require adaptability. Products and services change faster than supply chain processes, which were designed for traditional value propositions. As a result, the importance of alignment between functions like marketing, finance and supply chain is rising fast.

Companies are missing out on opportunities to improve their performance if they do not change their rigid supply chain processes. In other words, adaptive supply chain planning has become a crucial enabler for success for many companies.

How Do You Achieve Successful Supply Chain Planning?

The supply chain organization plays an important role in a company’s performance. And supply chain planning is the enabler to manage this performance. However, while trying to improve their performance, many companies forget about the principles for successful supply chain planning.

What Makes a Plan a Good Plan?

The first step towards successful planning is knowing how you currently perform and how you want to perform. Are you happy with your performance, and what performance metrics need improvement? When making plans, those plans should aim to meet these performance goals. This holds for the plans of all functions. This can only be achieved by having a common vision: what is a good plan? The question is simple, the answer is often more difficult. But once alignment is obtained, each function can optimize its strategy to create good plans: plans that contribute to aligned performance goals.

Close Performance Gaps to Drive Business Value

In business, individuals pursue diverse goals. Shareholders often prioritize financial targets but also increasingly pursue social responsibility goals. Customers seek exceptional service, using measures like responsiveness and reliability.

If the current performance does not meet target performance, there are performance gaps. Closing performance gaps creates business value. To drive improvement, you must be aware of the drivers of performance and how they impact performance. For example, for a manufacturing company, drivers of reliability may be the yield of production, the lead time of suppliers, and the planned capacity utilization. Drivers for asset utilization may be the variability of demand and the uptime of machines. These drivers and their values are the basis for root cause analysis.

How Do You Identify Root Causes of Performance Gaps?

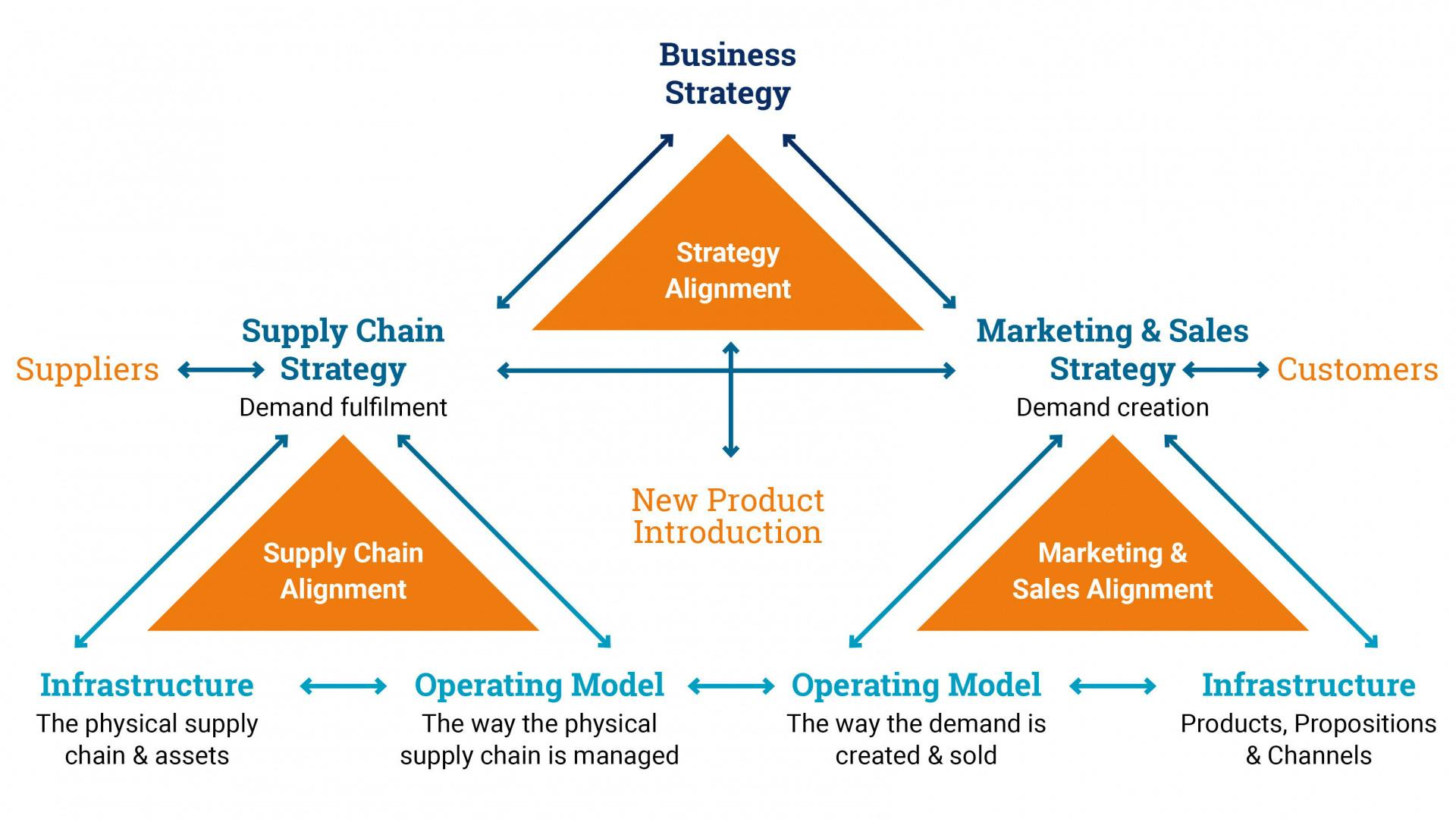

Based on an initial business alignment model from Cranfield University, we have developed an alignment model and assessment approach to identify supply chain improvement opportunities in a structured and effective way. The alignment model looks as follows:

The starting point is the business strategy, which we, for sake of simplicity, denote as the strategic performance goals that the company wants to achieve. To achieve those goals, demand must be created for the company’s products or services by Marketing & Sales. And that demand must be fulfilled by Supply Chain. The related strategies must be aligned to maximize opportunity and minimize risk. We call this strategy alignment. The supply chain strategy is the linking pin between strategy alignment and the optimization of the supply chain organization. The latter is denoted as supply chain alignment. The infrastructure must be designed to be fit for purpose to meet the supply chain strategic goals. And the operating model must be designed such that it optimizes the asset utilization to meet the goals.

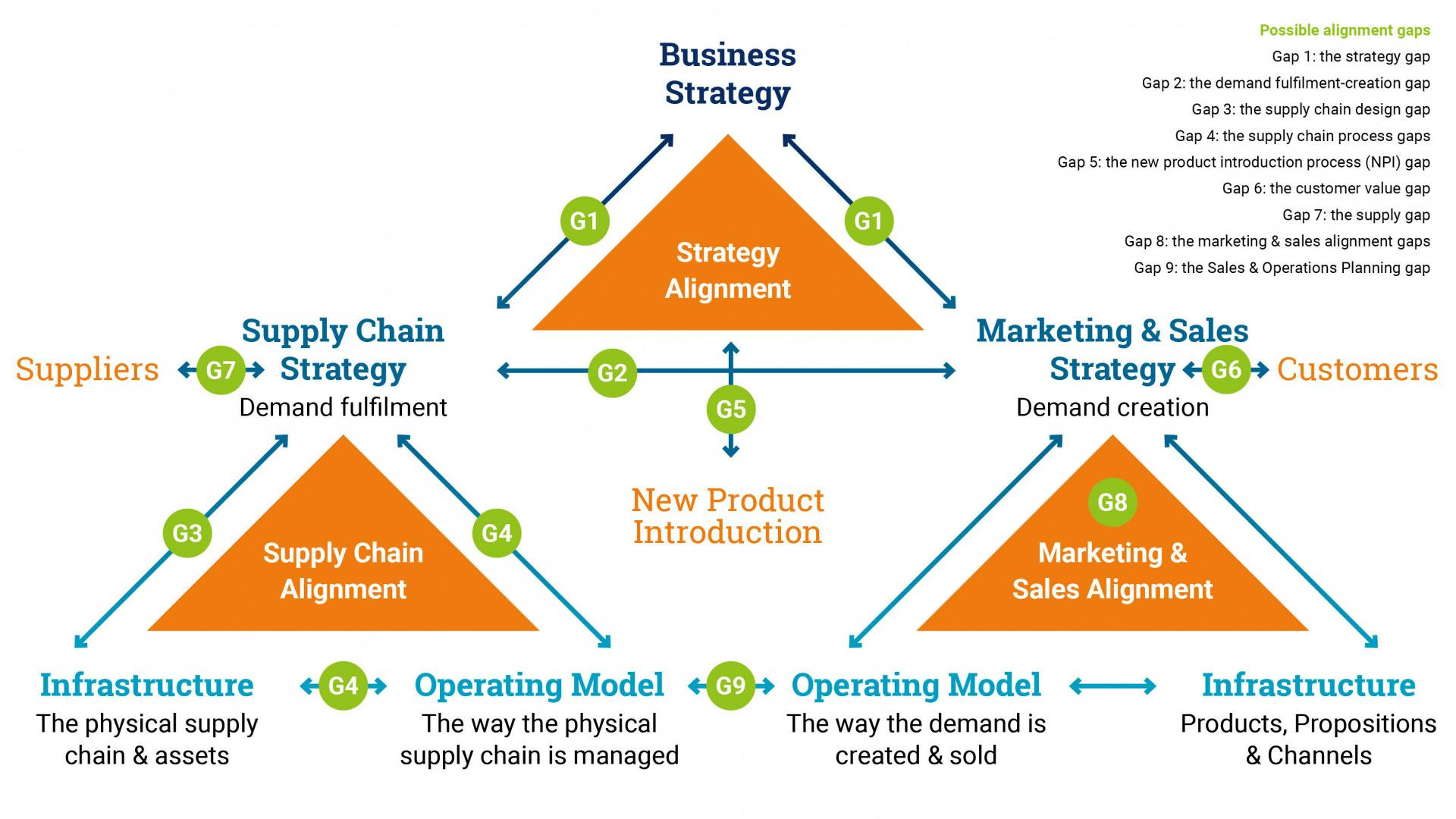

At each double arrow in the alignment model there can be a possible alignment gaps. Since we focus on supply chain optimization, we have identified those gaps that directly relate to supply chain. These are given below.

The power of this model is that the root cause of many performance gaps is often directly related to an alignment gap. Therefore, closing alignment gaps will result in great contribution to the improvement of business performance. Thus, assessing the alignment gaps of a company offers a very powerful way to identify root causes of performance gaps and give direction towards improvement opportunities to close those gaps.

The power of alignment is experienced best when involving all relevant stakeholders. By inviting each stakeholder to share his/her view on relevant performance metrics and on issues that inhibit reaching performance goals, a good insight will be obtained on business pains from many perspectives. By mapping those issues on the alignment model, a first impression is obtained of the most pressing alignment gaps. A further deep dive can then be performed to do a more profound analysis of gaps and root causes, possibly supported by data analysis for fact finding. We have experienced in projects with our customers that this alignment exercise is a very powerful instrument to understand the viewpoints from different functions and roles and to align on a common vision and goals. It helps to break down functional walls and get the noses in the same direction.

Don’t Jump to Tools Too Fast

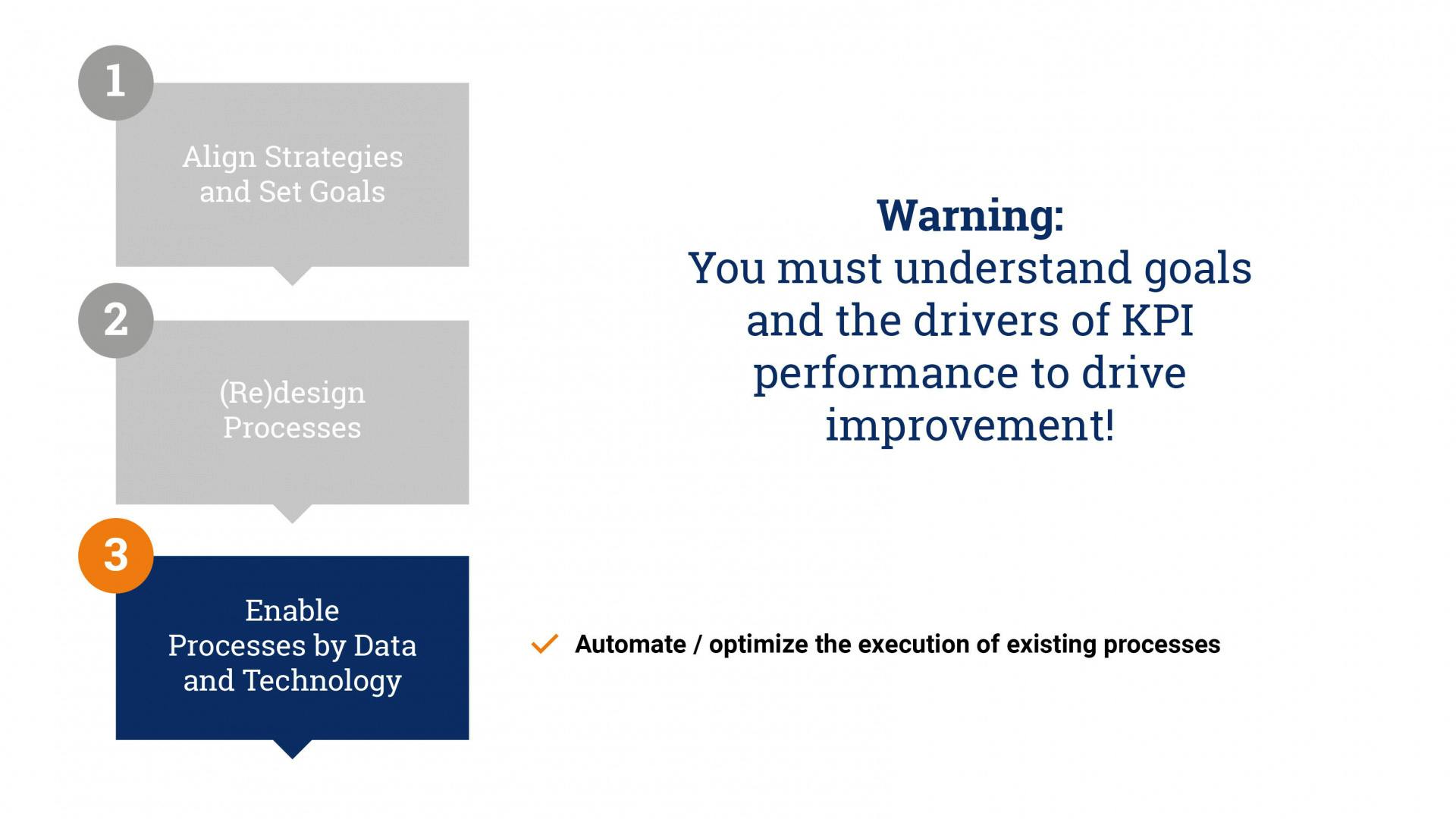

As we already mentioned, in many companies the processes have developed over time, and have not been adapted to the changes in goals, propositions or customer needs. Typical symptoms are a change of performance drivers or their (target values) and resulting performance gaps. Very often the reflex is to address the symptoms. If the delivery of goods is not sufficiently efficient, then we need better routing tools. And if the utilization of assets is too low, we need better forecasting tools. Such tools can be very useful, but they optimize the execution of the existing process.

Thus, instead of analyzing to what extent current processes are still fit for purpose to achieve business goals, companies often jump to tools to better support existing processes.

Optimizing the Supply Chain Processes

In many cases the biggest opportunity for improvement lies in the (re)design of supply chain planning processes. Changing environment or goals often call for different processes or policies. For example, if products are only produced to order, improved production scheduling may yield some improved asset utilization. But changing to production to stock for products with smooth demand may have much more impact. And if accepted demand is often not balanced with available capacity, then arranging flexible capacity may yield better reliability, but introducing a proper S&OP process to manage demand and supply will yield much more impact.

Thus, achieving your company's target performance requires the design of fit for purpose planning processes and policies that enable the right trade-off between often conflicting goals.

Support the Processes With Supply Chain Planning Tools

If the goals are clear and fit for purpose processes have been designed, then in many cases the optimal planning of these processes requires the support of planning tools. If these tools are meant to support newly designed processes, there may be many aspects involved to make a tool a success. Think of the impact that the change of process will have on people, and the requirements it has regarding data quality and availability and the integration in the IT landscape. Therefore, this final step towards successful planning needs to be addressed carefully. Once the requirements and feasibility have been assessed from all relevant perspectives, an ideal step is to perform a proof of concept on a small scale. If this proof of concept succeeds, a further industrialization and scale-up of the solution can be implemented.

Conclusions

Successful supply chain planning starts with a clear and shared vision on goals. Then the processes need to be (re)designed to meet those goals. And finally, the tools need to be in place to support the planning processes. Alignment is crucial to identify improvement opportunities and achieve the desired results.

Want to know more about how ORTEC can help you driving business value with successful supply chain planning? Contact us.

About Noud Gademan

As a Principal Consultant Supply Chain Optimization at ORTEC, Noud Gademann brings over 25 years of expertise in the optimization of Supply Chain Strategy and Planning. His strategic approach revolves around deep understanding of a company’s goals and value propositions and the supply chain processes to deliver these. He has worked with companies in many industries, including steel manufacturing, dairy, retail, energy infrastructure, warehousing and logistics, and rail services. He loves to combine his broad industry experience with his knowledge of optimization techniques and supply chain best practices to create business value for companies. In recent years he has focused on high-tech manufacturing, helping companies to manage variability and uncertainty and deal with capacity constraints.

Want to know more?

Want to know more about how ORTEC can help you driving business value with successful supply chain planning