AI Agents in the Supply Chain Ecosystem: The Digital Twin Learns to Talk

Supply chains are complex ecosystems where communication and collaboration are often challenging. Fragmented processes, conflicting KPIs, and hesitancy to share data make end-to-end collaboration difficult.

Generative and Agentic AI offer new opportunities to share information more intelligently and more quickly, and to better understand interactions within the chain. This is the domain of the digital twin.

In this article, we explore how AI agents, working autonomously but within clear boundaries, can contribute to more efficient and better-aligned supply chain ecosystems.

At ORTEC, we work every day on improving alignment in supply chains. Together with Supply Chain Media, we explore how AI agents can set a new standard.

This article was created in collaboration with:

- Martijn Lofvers, CEO & Chief Trendwatcher, Supply Chain Media

- Sander Vlot, VP Center of Excellence at ORTEC Data Science & Consulting

- Frans van Helden, Executive Vice President (EVP) of ORTEC’s Supply Chain Planning Division

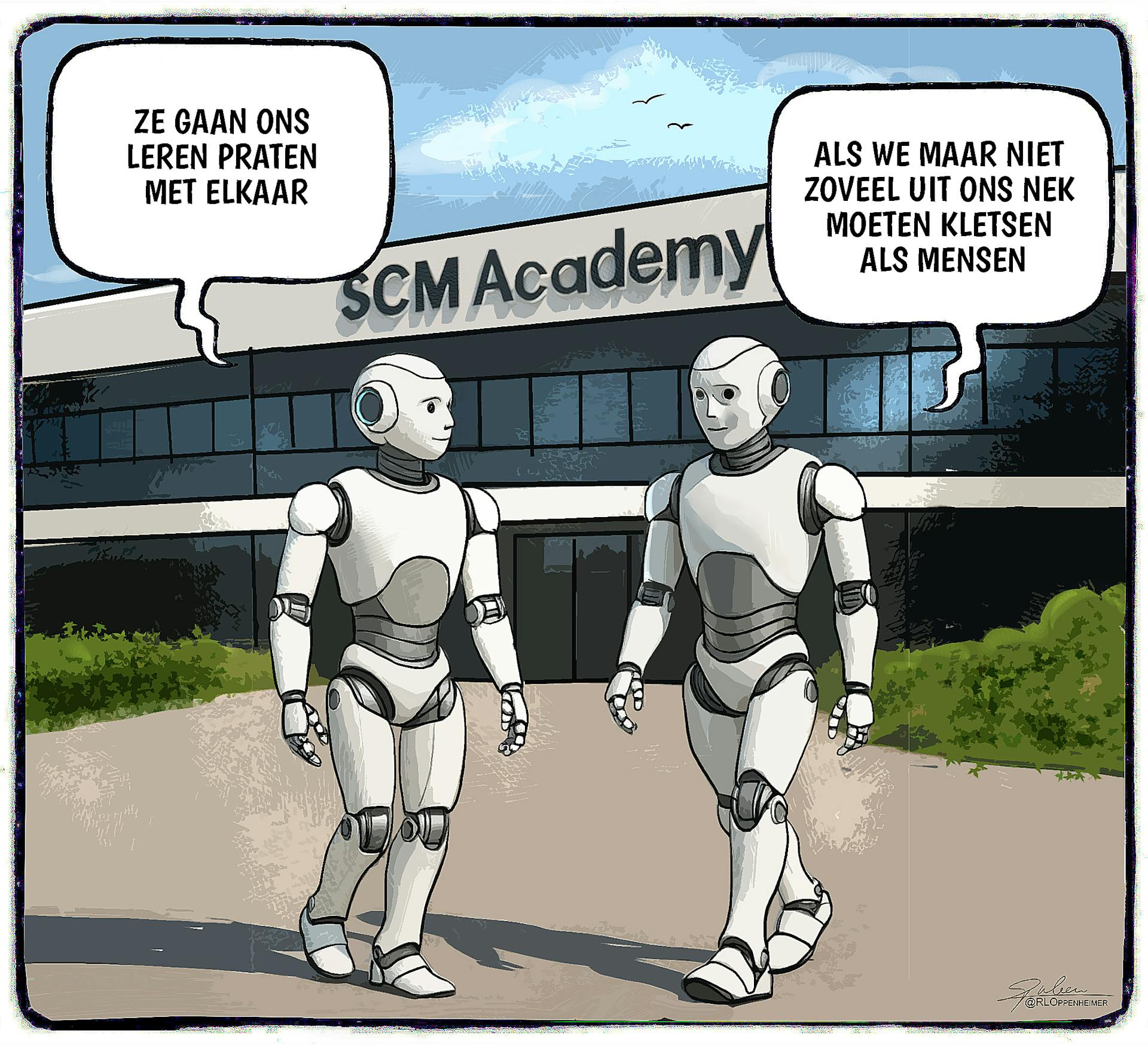

- Cartoon: Ruben L. Oppenheimer

Read the original article as published in Dutch in Supply Chain Magazine (oktober 2025). Download the article (in Dutch)

A Supply Chain Is Not a Machine but an Ecosystem

End-to-end supply chain optimization is the holy grail of our field. Not only should our own network of factories, warehouses, and distribution centers work together optimally, it must also connect seamlessly with suppliers and customers. The entire ecosystem is included in this scope. The term “supply chain” already implies it: it is a chain, not just a few loose links.

In practice, the ideal of a seamlessly managed chain often seems like a fool’s hope. It is already difficult to make different departments and planning processes within one company communicate effectively, let alone with external partners. Demand, supply, and financial planning each have their own KPIs, priorities, and ways of working. The result is a complex machine whose gears rarely align perfectly.

A supply chain is not a machine but an ecosystem. The difference lies in how its parts communicate. Planning processes don’t exist in isolation; they define conditions for one another. There are many examples of organizations that have already made major progress. For example, HEINEKEN achieves European synergy in its supply chain even though planning was originally done at the country level.

The need for communication does not stop at the boundaries of the organization. Sensitivity around strategic information and competition hinders data sharing, which prevents true end-to-end visibility. KPIs and processes of different partners align even less. The way disruptions are handled also differs between organizations. Even in best-in-class supply chains such as the high-tech ecosystem around ASML, achieving ecosystem optimization is a complex and labor-intensive goal. All partners must continuously invest in collaboration and communication.

Attempts to improve communication within and between large organizations through technology are nearly endless. ERP systems, S&OP processes, data sharing, and even blockchains once promised to solve everything. This is why the introduction of yet another solution should always be approached critically. And yet, we want to give it a try.

By better connecting processes and using information more quickly, AI agents can contribute to smarter, more efficient, and better-aligned supply chains. The potential is significant, and it is time to explore it.

Do AI Agents Spark a Supply Chain Revolution?

Generative and agentic AI have already shown what they can do in marketing. They automate decision-making and help organizations respond more quickly to customer needs. That same technology now presents a major opportunity in supply chains. By connecting processes more effectively and using information faster, AI agents can help build smarter, more efficient, and better-aligned supply chains. The potential is enormous, and the time has come to explore it.

AI agents are an extension of generative AI. They do not just use Large Language Models to generate text; they can also plan and perform tasks autonomously. AI agents can have different levels of autonomy. In supply chains, we mainly see potential in agentic workflows, where LLMs can perform tasks but only within predefined paths. Well-designed agentic workflows are controllable, do exactly what they are asked to do, are disciplined, and therefore highly predictable.

Since the introduction of agentic AI, automation has attracted renewed interest, and for good reasons. Time is a scarce resource in supply chains. Under time pressure, people can become careless, overlook details, and forget rules, also in communication. This is not criticism but just an observation. To automate communication effectively, we must be willing to let AI agents handle part of it.

Agents will need access to data from internal systems such as ERP, planning tools, and inventory information. They must understand the objectives and KPIs they are working with and know which data they may or may not share. With that foundation, they can communicate continuously with other agents or with people. The fact that communication becomes artificially intelligent makes data and information exchange far more effective than the flat data exchange that was long seen as the solution for chain collaboration. With the introduction of LLMs in the supply chain, we are taking an important step forward in the familiar field of the digital twin. We are teaching it to talk.

AI agents will become part of communication in the supply chain. But it is up to us to make sure it becomes a meaningful conversation. If we focus only on technology, we will not move forward. If we focus on alignment and on sharing the right information quickly, precisely, and in a disciplined way, we will.”

A Crucial Role for Leadership in a Fast-Moving Market

There is currently a lot happening in this field. Systems are being connected to AI agents through the Model Context Protocol, and recently there has been a consolidation in so-called agent-to-agent protocols. While this article was being written, a new example emerged in which teams at Harvard and MIT had AI agents play the traditional “beer game” entirely by themselves. This produced interesting insights into the theory and practice of information sharing.

AI agents alone will not cause a supply chain revolution, just as the gradual rise of digital twins did not. In the end, it is human supply chain leaders who must commit to broad collaboration or accept the consequences of silo thinking, with all the resulting bullwhip effects. Human leadership determines how IT truly serves us.

AI agents will become part of communication in the supply chain. But it is up to us to make sure it becomes a meaningful conversation. If we focus only on the technology, we will not move forward. If we focus on alignment and on sharing the right information quickly, precisely, and in a disciplined way, we will. Once that communication is in place, we can move on to the real goal: supply chain optimization.

A Supply Chain Is Not a Machine but an Ecosystem

The difference lies in the communication between its parts. Planning processes do not exist in isolation; they define conditions for each other. Many organizations have already made major progress in this area. Would you like to know what this could mean for your organization? Contact us to learn more.

About Sander Vlot

"Sander Vlot has always been curious about how complex systems work, and how to make them work even better. As VP Center of Excellence at ORTEC, he leads a team exploring cutting-edge applications of Machine Learning, Mathematical Optimization, and (Generative) AI to help organizations make smarter planning decisions, primarily in supply chain management. With a sharp eye for scientific and technological trends, Sander enjoys pushing the boundaries of what’s possible, without losing sight of what really works. Since joining ORTEC in 2015, Sander has worked closely with leading companies in high tech manufacturing, logistics, and retail to design and build state-of-the-art planning and scheduling solutions that leverage the power of mathematics and AI."

About Frans van Helden

"As the Executive Vice President (EVP) of ORTEC’s Supply Chain Planning Division, Frans aims to exceed client expectations by consistently delivering tangible and lasting value. His commitment to diversity and the integration of technology into business processes stands out, reflecting a forward-thinking and client-centered leadership style. By making ORTEC’s software offering more scalable and expanding the portfolio in line with ORTEC’s continuous improvement philosophy, Frans expects substantial growth over the coming years in both the Americas and Europe."

Stay up to date

Subscribe to our quarterly newsletter