How Load Optimization Improves Logistics Efficiency in Europe (2025)

Shipping capacity in Europe remains scarce and expensive in 2025. This article explains how load optimization helps manufacturers and logistics providers maximize resource utilization, lower costs, and stay compliant with EU regulations.

By Stefan Althoff, VP Product at ORTEC

Want to deepen your understanding of advanced load building and order optimization? Explore our E-Guide "Carton, Pallet, and Load Optimization: Business Scenarios and Benefits" for valuable insights and strategies, or check out one of our best read articles “4 Scenarios for Optimized Pallet and Load Building in SAP Transportation Management".

Logistics challenges across Europe in 2025

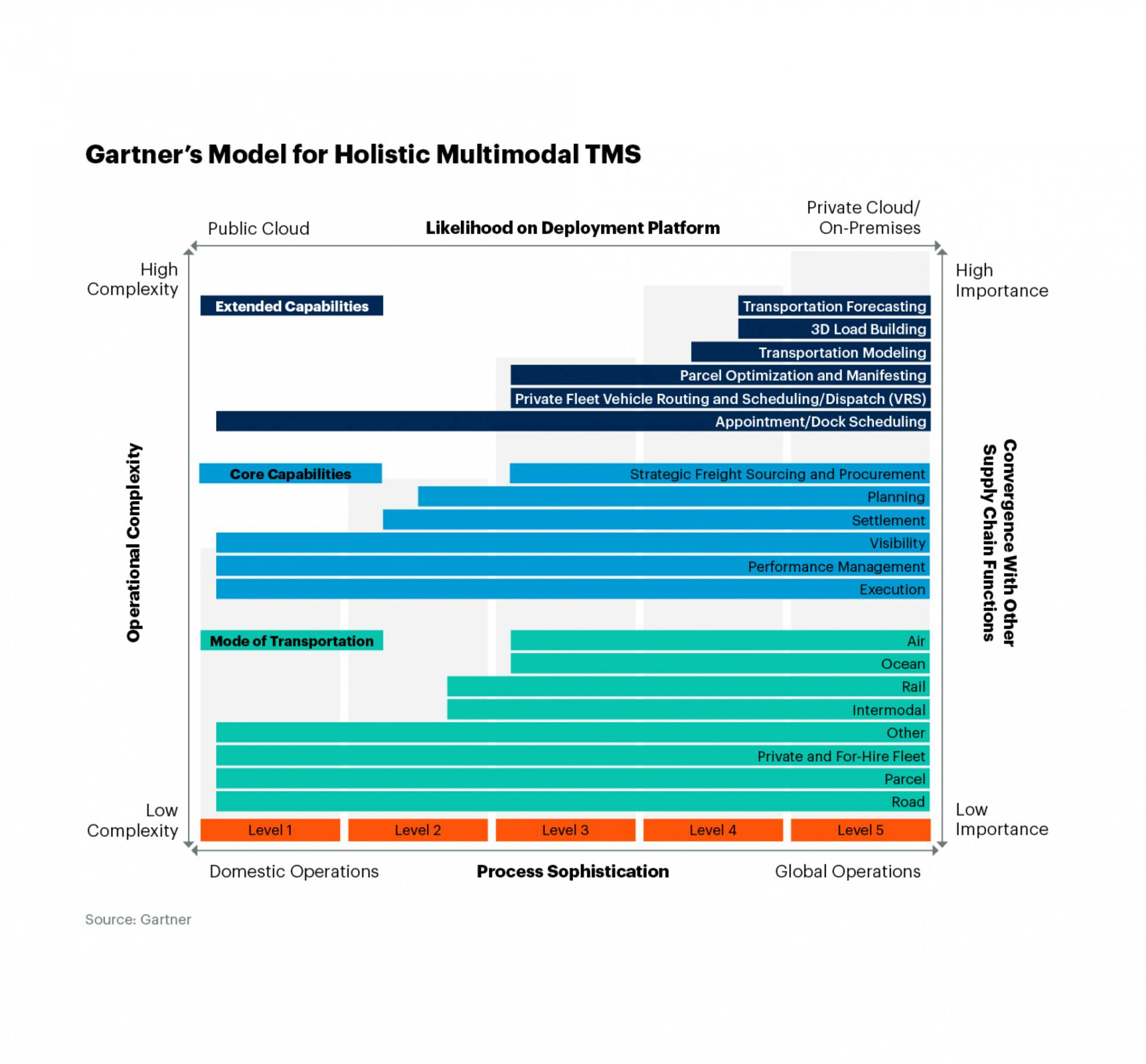

Traditionally, manufacturing companies have viewed transportation as a “necessary evil.” As Gartner notes, it’s the function organizations “often target for budget cuts.”

Today, European logistics is defined by high fuel prices, stricter EU sustainability regulations, driver shortages, and fluctuating freight rates. An approach focused only on cutting costs is no longer effective. Instead, companies are adopting new technologies to improve efficiency, agility, and compliance.

Load optimization is one of the most effective strategies to address these challenges. It helps maximize resource utilization, reduce cost per shipped SKU, and ensure high-demand products move quickly across complex EU supply chains.

Scarce and expensive transport capacity in Europe

Road freight rates in Europe remain above pre-2020 levels, according to industry benchmarks. Cross-border trucking is further impacted by driver shortages and compliance with the EU Mobility Package, which regulates working hours, rest periods, and wages. Rising energy costs add another layer of complexity.

When transport capacity was abundant and inexpensive, companies often shipped full truckloads or containers with a single product. In today’s volatile European market, this strategy is no longer cost-efficient.

Ship the right products across the EU

With limited transportation capacity and high freight rates, manufacturers must prioritize shipments for products that are truly in demand. They also need to make maximum use of every truck and container.

In practice, this means mixing products with different dimensions, stacking rules, and demand priorities into optimized loads—whether shipping within Germany, across Benelux, or from Central to Southern Europe.

Manual planning takes too long and lacks flexibility. Most ERP, WMS, and TMS tools only consider weight and volume, without accounting for real-world European requirements such as axle weight limits, pallet variations, or cross-border restrictions.

Advanced load optimization software solves this problem. ORTEC’s 3D load building solution combines mathematical optimization, industry expertise, and cloud technology into an easy-to-use tool for European manufacturers and logistics providers.

What is 3D load building?

Gartner highlights 3D load building as a critical capability for modern transportation management. The technology uses advanced algorithms to propose optimal load configurations, taking into account:

- Actual package dimensions

- Physical, legal, and business-specific rules

- EU road safety regulations and weight restrictions

This ensures companies not only maximize capacity but also remain compliant across European markets.

Reducing logistics risks with ORTEC load optimization

ORTEC's cloud-native 3D load building software allows companies to optimize packing and loading in a flexible, scalable way. It integrates seamlessly with existing systems, without requiring extensive IT investments.

Analysts recognize ORTEC as a leader in load optimization. On average, customers increase fill rates by 5%. At today’s European freight rates, that translates to €120–€150 in savings per container. Companies typically reduce logistics costs by 3–7% by improving freight utilization across parcel, LTL, FTL, road, and sea transport.

Additional benefits include:

- Avoiding costly repacking

- Ensuring pallet stability in compliance with EU rules

- Selecting efficient carton sizes for parcel shipments

- Gaining transparency and visibility across the entire EU supply chain

Image: Mitigate logistics risks with load optimization

Building agility into European supply chains

With ORTEC’s SaaS-based load optimization, business rules and logistics data are stored securely in the cloud. This makes it easy to set up new operations or onboard logistics partners anywhere in Europe—without lengthy IT projects.

Companies can apply consistent quality standards across all partners, ensuring everyone works with the same master data, packing and loading rules, and optimization functionality.

Why ORTEC is the leading choice for European logistics

If you’re looking to improve efficiency in European logistics and make the best use of your transport capacity, feel free to reach out. We’ll be happy to schedule a demo of our solution.

Improve your efficiency in European logistics and make the best use of your transport capacity.

Request a personalized demo today and discover how ORTEC’s 3D Load Optimization can help your company cut costs, increase efficiency, and stay compliant with EU transport regulations.

FAQ: Load Optimization in European Logistics (2025)

How can European companies reduce logistics costs in 2025?

European companies can reduce costs by using 3D load optimization, which improves fill rates by up to 5% and lowers freight and labor costs by 3–7% on average.

What EU regulations affect freight and logistics?

Key rules include the EU Mobility Package, axle weight restrictions, and pallet size standards. Load optimization software helps ensure compliance.

Why is load optimization critical for European supply chains?

With driver shortages, high energy prices, and cross-border complexity, load optimization ensures trucks and containers are filled efficiently, reducing wasted space and cost.

Can load optimization support sustainability goals in the EU?

Yes. By increasing fill rates, companies ship fewer trucks and containers, lowering CO₂ emissions and helping meet EU sustainability targets.

What makes ORTEC’s 3D load optimization different?

ORTEC combines advanced mathematics, cloud technology, and decades of logistics expertise, making it the leading solution for European manufacturers and logistics providers.