Smarter Business Decisions with Structured Scenario Planning

Read time: 6-7 minutesScenario planning offers organizations a practical way to navigate uncertainty and make smarter decisions. Sander Vlot, VP Center of Excellence at ORTEC Data Science & Consulting, shares how structured scenario planning results in more actionable plans compared to classical 'what-if scenarios' - improving strategy, resilience, and transparency.

Interview with Sander Vlot, VP of the Center of Excellence at ORTEC Data Science & Consulting

Structured Scenario Planning for Business Uncertainty

Scenario planning offers organizations a pragmatic and powerful way to make decisions in an uncertain world. By structurally separating choices and uncertainties, it creates space for more actionable decision-making—without falling into mathematical complexity or the illusion of false precision. With the right tools, methodology, and mindset, organizations can better prepare for the future. Whether it's about supply chains, investments, workforce planning, or innovation: scenario planning helps navigate uncertainty. “For many companies, this is the optimal solution for tactical and strategic challenges,” says Sander Vlot, VP of the Center of Excellence at ORTEC Data Science & Consulting. “It’s a realistic, workable step forward—and that’s exactly what organizations need right now.”

Whether it’s supply chain disruptions, geopolitical tensions, climate change, or shifting consumer behavior—companies are in dire need of structure in an increasingly complex world. That’s why scenario planning is growing in popularity—not as an abstract mental exercise, but as a concrete tool to support decision-making under uncertainty. “Many companies struggle to combine their strategic or tactical choices with multiple future scenarios. Most planning systems simply aren’t built for that,” says Vlot. “At ORTEC, we’re developing methods to make that complexity manageable—to avoid falling into the trap of false certainty.”

Growing Urgency: From Efficiency to Business Resilience

The need for this approach is becoming increasingly clear. For years, supply chains were all about efficiency: lean operations, just-in-time delivery, cost minimization. But that focus also led to vulnerability. One disruption—like the COVID-19 pandemic or chip shortages—can upend an entire chain.

Scenario planning forces organizations to think ahead. Not by trying to predict exactly what will happen, but by preparing for a range of plausible futures. That makes it possible to make decisions that hold up under a variety of conditions. “We’re seeing that companies now realize pure efficiency isn’t enough anymore,” Vlot notes. “There’s a clear shift toward resilience and risk diversification. That demands different decisions, different trade-offs—and therefore, different tools.”

“You avoid the complex math, but you can still make deliberate trade-offs between risk, return, and robustness."

- Sander Vlot, VP Center of Excellence at ORTEC

From “What If” to Structured Scenario Planning

Traditional planning processes often rely on a single version of the truth: one forecast, one plan, one outcome. In a predictable world, that works just fine. But increasing volatility has rendered this approach outdated. Organizations that want to explore different scenarios side by side—and make deliberate trade-offs between them—quickly run into both technical and conceptual limitations.

Most ERP planning modules make it difficult to set multiple versions of reality alongside each other. And when they do, it’s often just flat lists of scenarios where uncertainties and decisions are lumped together. That, according to Vlot, makes it difficult to arrive at robust choices. “What we often see is that companies create different scenarios but mix up uncertainties—like demand and supply fluctuations—with decisions, such as investments in capacity. In that case, you are essentially calculating which investments would make most sense for individual possible futures. However, since you can't pick your favorite future, you still don't know which investments provide the best balance of efficiency, risk, and resilience across all possible futures. That makes these mixed scenarios less actionable."

The Power of Separation: Decision-Making vs. Uncertainty

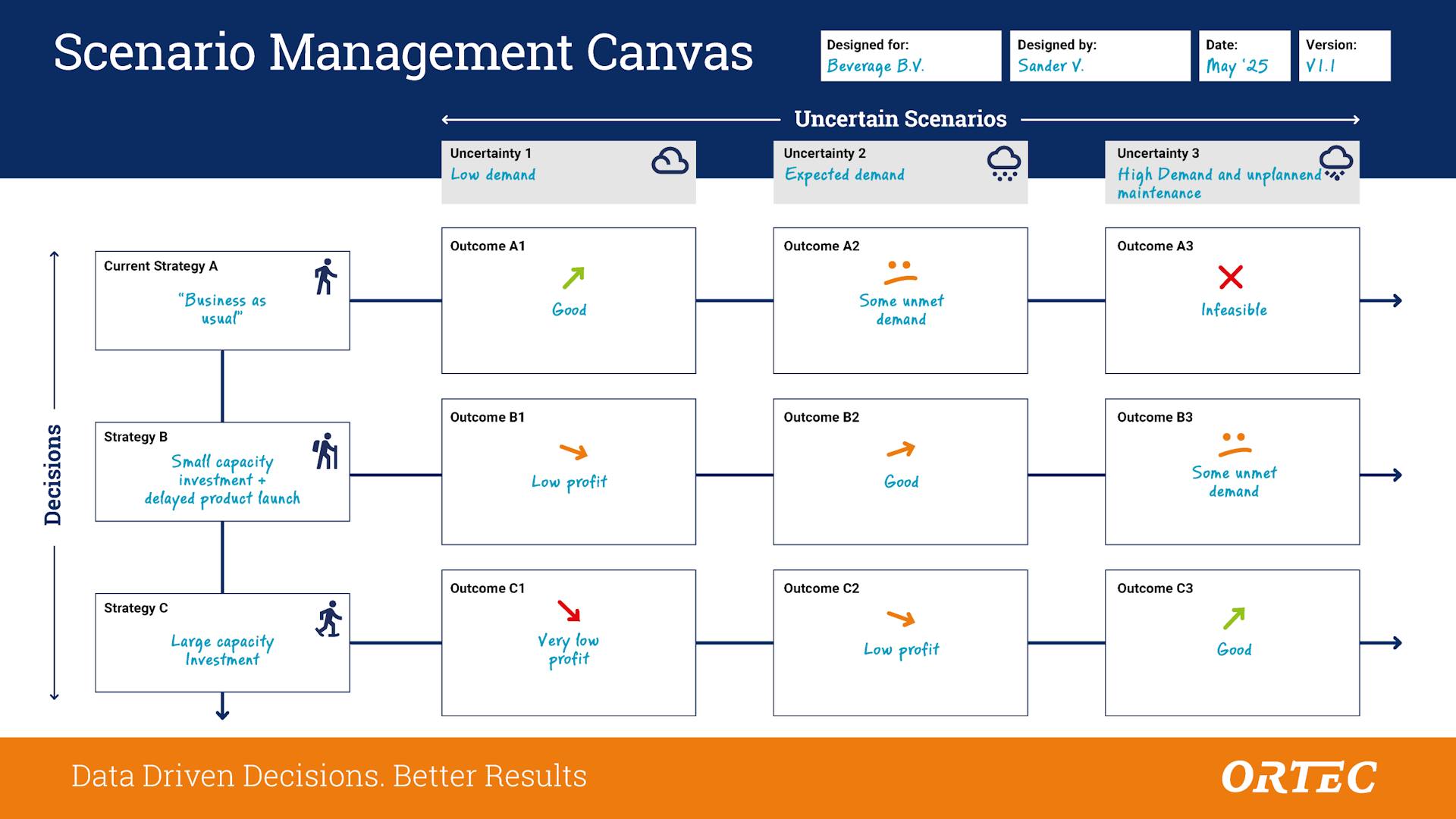

An effective approach starts by explicitly separating what you know (or can decide) from what you don’t know. That means building scenarios that describe different forms of uncertainty (e.g., low, expected, and high demand, but also, different forms of supply uncertainty), and clearly defining the decisions your organization can make (like whether or not to invest in additional production capacity, or to change the timing of a promotion or a new product introduction).

Placing these two dimensions into a matrix creates a powerful analytical framework - to be seen in our Scenario Management Canvas above. Each box in the matrix represents one possible outcome: a specific decision under a specific future scenario. You can then calculate the outcome of each choice under varying circumstances. “Among ourselves as mathematicians, we see it as a form of ‘stochastic programming by hand,” Vlot explains. “It’s a pragmatic form of optimization that doesn’t require calculating probability distributions. Instead, you make your own trade-offs between cost, risk, and robustness. For planners, it’s simply a very clear and structured way to deal with decision-making under uncertainty.”

Download your own Scenario Management Canvas

Download a free, blank copy of our Scenario Management Canvas.

From "what if..."

... to Structured Scenario Planning

Sander Vlot, VP Center of Excellence at ORTEC

"We’ve built tools that let users literally click scenarios together. That lowers the barrier significantly. You don’t need to be a data scientist anymore to work with scenarios."

A Flexible Planning Environment for Better Decisions

What makes this approach so powerful in practice is the support of flexible software. “We often build software that sits on top of ERP systems or other planning software,” Vlot explains. “We don’t replace those systems; we integrate with them. If you see your ERP system as a ‘system of record’—primarily focused on the uniform storage of transactional business data—then our solution acts as a ‘system of decision intelligence.’”

ORTEC develops applications that allow users to build their own scenarios, for instance by quantifying the impact of risks and opportunities and toggling them on or off in various scenarios. Think of scenarios where the summer is exceptionally good (which can affect customer demand), a supply route is temporarily blocked, or a factory needs early maintenance. Or events on the demand side, like a competitor entering the market or changing their prices.

These factors can be analyzed in combination, offering insights into how resilient the supply chain is under different conditions. “We’ve built tools that let users literally click scenarios together,” says Vlot. “That significantly lowers the threshold. You no longer need to be a data scientist to work with scenario planning.”

“Sometimes, simple machine learning models are accurate enough—and much faster to evaluate. That enables large-scale scenario analyses without sacrificing too much quality.”

- Sander Vlot, VP Center of Excellence at ORTEC

Technology as a Catalyst in Scenario Planning

The rise of scenario planning is closely tied to advances in technology. Increased computing power, better data availability, and the rise of machine learning have made it easier to generate and evaluate forecasts. “Machine learning is increasingly being used to support decision-making,” says Vlot. “ML-based forecasting can now generate multiple future scenarios. That’s already a step beyond traditional forecasting, which usually only offers one outlook. The added value of the planner is that they can include additional knowledge in the form of risks and opportunities—things that aren’t always visible in the data. That results in an augmented forecast. You can then use those scenarios to stress-test strategic and tactical decisions.”

The combination of forecasting and scenario planning creates a natural learning loop as illustrated below, consisting of the following phases: predict, prepare scenarios, plan, execute, monitor, improve - and start over. This allows companies to continuously learn from reality and refine their decisions.

With the success of scenario planning, there’s increasing demand to calculate ever-larger numbers of scenarios. “Classical optimization methods are accurate, but relatively slow,” says Vlot. In some cases, simpler machine learning models are accurate enough and—after training—much faster to evaluate. “That enables large-scale scenario analyses without giving up too much in terms of quality.”

Sander Vlot, VP ORTEC Center of Excellence

"In many organizations, gaining a consolidated overview —like simulating inventory levels across countries—is an important first step. From there, you can start working with scenarios."

Structured Planning As A Way of Thinking

Scenario planning isn’t a one-time exercise—it’s a discipline. It requires a shift in how organizations think: dealing with uncertainty in a more structured way, improving data consistency between departments, and centrally organizing decision support.

“What we often see with clients is that it not only results in better plans, but also more transparency,” Vlot says. “In many organizations, gaining a consolidated overview —like simulating inventory levels across countries—is an important first step. From there, you can start working with scenarios."

Implementation doesn’t come without challenges. Different countries or business units often use different definitions, systems, and assumptions. But if you can overcome those barriers, you lay a strong foundation for forward-looking planning.

About Sander Vlot

Sander Vlot has always been curious about how complex systems work, and how to make them work even better. As VP Center of Excellence at ORTEC, he leads a team exploring cutting-edge applications of Machine Learning, Mathematical Optimization, and (Generative) AI to help organizations make smarter planning decisions, primarily in supply chain management. With a keen eye for scientific and technological trends, Sander enjoys pushing the boundaries of what’s possible, without losing sight of what really works. Since joining ORTEC in 2015, Sander has worked closely with leading companies in (high-tech) manufacturing, logistics, and retail to design and build state-of-the-art planning and scheduling solutions that leverage the power of mathematics and AI.

Smart Decisions Start with the Right Insights

Stay informed with expert insights, industry trends, and practical strategies that help you stay ahead. Subscribe now to get the latest updates straight to your inbox.