The Comprehensive Guide to Integrated Routing & Loading for Producers

Learn how to achieve new efficiency, cost savings, and sustainability for your production and distribution operations.

Dive into a practical and strategic overview of integrated routing and loading. This exclusive E-Guide walks you through the latest methods to optimize pallets, trailers, and routes, powered by real-world producer examples and actionable business insights.

What Global Brands Do We Serve?

When Is This Guide Right for You?

Today’s manufacturing and production supply chains face rising demand, tighter cost pressures, and increasing expectations for sustainability and reliability. If any of the following sound familiar, this guide is for you:

- Maximizing Efficiency: Learn how to streamline operations, improve trailer and pallet utilization, and reduce empty miles.

- Cutting Costs Without Compromise: Discover ways to reduce shipping, labor, and operational costs through optimized routing and load planning.

- Meeting Sustainability Goals: Reduce carbon emissions and waste by making the most of every pallet and trailer.

- Adapting to Dynamic Demand: Manage fluctuations, spikes, and complex multi-location deliveries while maintaining service excellence.

This guide is designed for producers, manufacturing leaders, and supply chain managers looking to enhance operational efficiency, deliver exceptional customer service, and meet sustainability targets. Whether you’re just starting with digital optimization or refining an advanced logistics network, this guide provides practical value on every page.

Why Read This Guide?

Understanding integrated routing and loading is essential for cost-efficient, sustainable, and customer-focused manufacturing logistics. This E-Guide distills global best practices, proven tools, and actionable recommendations from leading producers and logistics experts. You will discover:

- Expert guidance on optimizing load building, 3D pallet stacking, and route planning; what it is, and how it works for you

- Lessons from major manufacturers, showing measurable cost reductions, improved on-time deliveries, and optimized trailer utilization

- Real-world business impact: Producers that adopt integrated routing and loading optimization report up to 24% more space utilization and significant reductions in transport costs and carbon emissions

- A clear pathway to implement advanced logistics optimization without disrupting existing operations

Did you know?

- Up to 20% of trucks currently travel empty in manufacturing logistics.

- Implementing integrated routing and loading can reduce empty miles, improve capacity utilization, and help producers meet sustainability goals.

- Companies using optimization platforms see measurable improvements in delivery efficiency, customer satisfaction, and environmental impact.

Who Should Read This Guide?

If improving operational efficiency, reducing transportation costs, and meeting sustainability targets matters for your business, this guide will help you navigate challenges and implement proven solutions.

This E-Guide is a valuable resource for:

Manufacturers & Producers

Supply Chain & Logistics Managers

Warehouse & Operations Leaders

Sustainability and Environmental Compliance Officers

Ready to Transform Your Production and Distribution Operations?

Start reading now and discover how integrated routing and loading can maximize efficiency, reduce costs, and support your sustainability goals; all while delivering better service for your customers.

Integrating Routing and Loading to Maximize Supply Chain Efficiency

Table of Contents

Introduction: Challenges and Opportunities in Finished-Goods Logistics

Why Integrating Routing and Loading Matters

Step 1: Optimizing the Size and Structure of Each Order

Step 2: Combining Orders to Maximize Load Utilization

Additional Strategies for Higher Load Utilization

Integrating Process and IT

Customer Success Stories

Conclusion: Deliver More with Integrated Routing and Loading

Introduction: Challenges and Opportunities in Finished-Goods Logistics

Producers today face growing complexity across the supply chain. From sourcing raw materials to meeting higher service-level expectations, inefficiencies in transportation and warehouse management can quickly increase costs and reduce customer satisfaction.

Key challenges include:

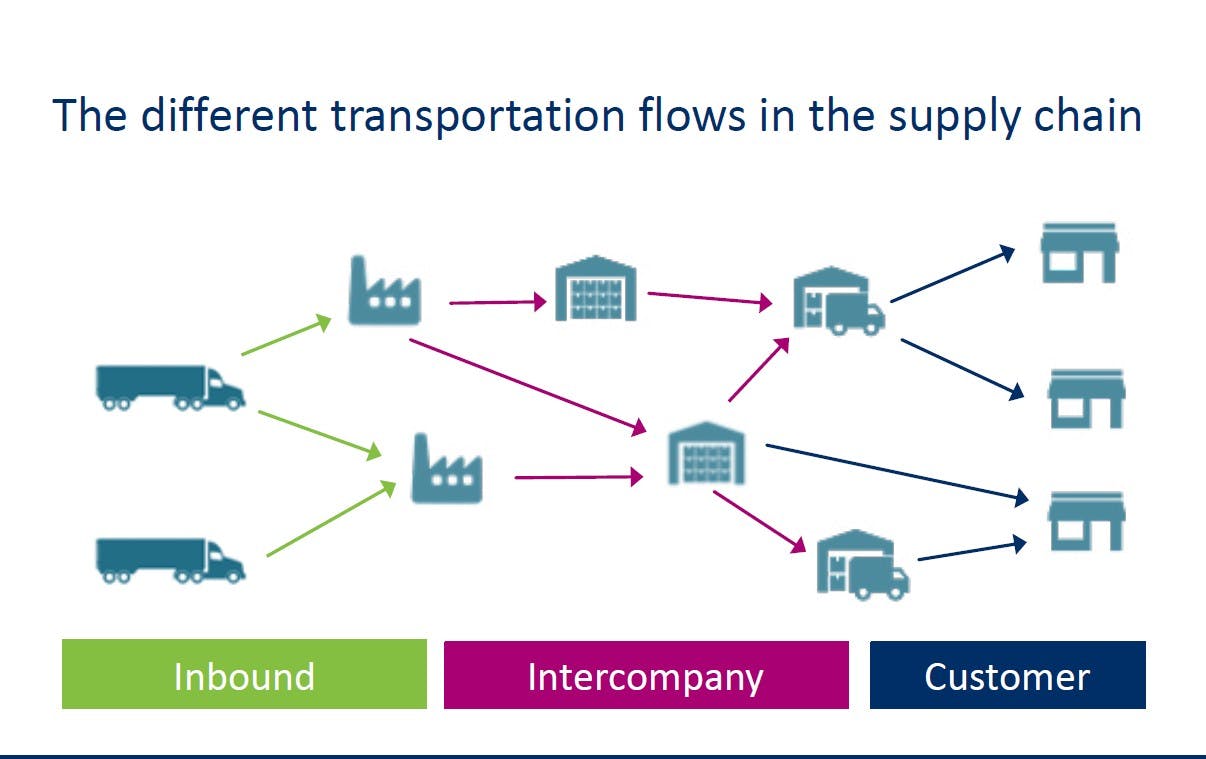

Inbound: Uncertainty and delays from suppliers for raw materials and components.

Internal: Rising labor costs and decisions on when to replenish stock or transfer inventory between warehouses.

Outbound: Fluctuating demand, delivery spikes, and increased service-level expectations.

These inefficiencies have measurable impacts:

- Truck and container utilization averages only 57%.

- About 20% of trucks travel empty.

- Pallets are often underutilized, leaving valuable space wasted.

These challenges also present significant opportunities:

- Up to 24% savings in empty space, potentially reducing the need for 3.5 million containers.

- On-demand packaging solutions can lower shipping costs for commercial customers by up to 35%.

Better utilization of pallets and trailers can help producers reduce carbon emissions and meet sustainability goals, such as cutting emissions by 50% by 2030, aligning with both customer and societal expectations.

With logistics software, transportation management systems, and advanced optimization engines, producers can integrate routing and loading to unlock these benefits.

Why Integrating Routing and Loading Matters

Combining routing optimization and load optimization creates measurable value for producers across transportation, operations, and customer service.

Benefits include:

- Improved trailer and pallet utilization

- Reduced empty miles and fuel consumption

- Higher delivery reliability and customer satisfaction

- Support for sustainable logistics initiatives

By integrating transportation management software (TMS) with order and warehouse data, producers can achieve cost savings and operational improvements while maintaining flexibility in complex supply chains.

Step 1: Optimizing the Size and Structure of each Order

Every order consists of multiple items that must be stacked efficiently on load carriers like pallets. Using logistics software and warehouse management systems, producers can consider:

- Product dimensions and stacking orientations

- Pallet height limits and warehouse constraints

- Stability rules for safe transport

A modern optimization engine can create pallets that are:

- Loading-friendly: Fits warehouse layout and handling processes

- Transport-friendly: Respects weight distribution, axle load, and stability

- Unloading-friendly: Aligns with customer preferences and delivery sequence

This step not only improves loading efficiency but also reduces costs and simplifies downstream transportation and unloading.

Step 2: Combining Orders to Maximize Load Utilization

Once individual pallets are optimized, multiple orders can be combined into one load. Traditional routing software only considers simple metrics such as total volume or weight.

By using a 3D loading optimizer integrated with routing software, producers can:

- Minimize empty space while respecting all constraints

- Align loads with warehouse, driver, and receiver preferences

- Reduce mileage, fuel consumption, and transport costs

This approach ensures maximum load utilization and operational efficiency.

Additional Strategies for Higher Load Utilization

Product Design: Adjusting product size or strength can increase the number of items per pallet or layer, improving overall efficiency.

Splitting Orders: Large, less-than-truckload shipments can be split across multiple routes to optimize delivery schedules and reduce costs.

Fillers: Fast-moving products can fill leftover pallet or trailer space for regular deliveries, reducing empty space.

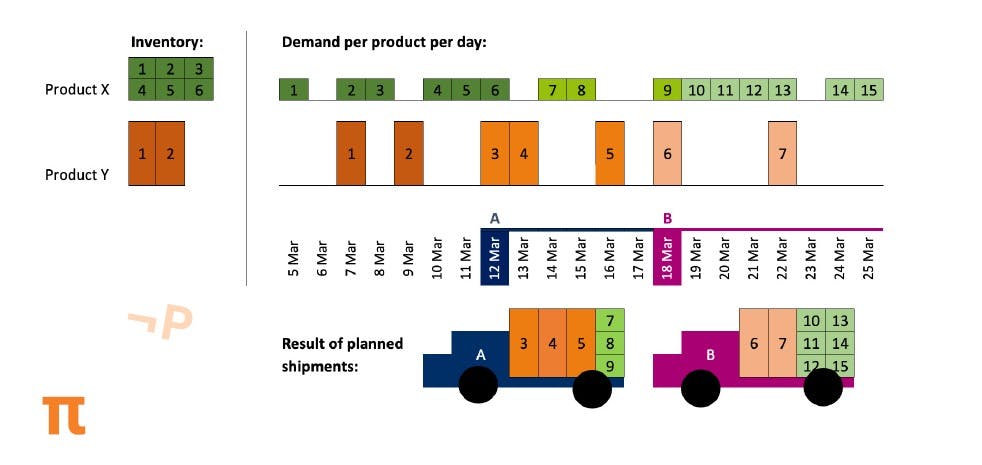

Optimization at the Demand Level: Using demand forecasting software and supply chain planning tools, producers can schedule deliveries to ensure inventory meets demand while optimizing load capacity.

Example below: If the optimizer knows demand for multiple products over 20 days, it can schedule deliveries that maximize trailer fill while respecting all loading constraints.

Integrating Process and IT

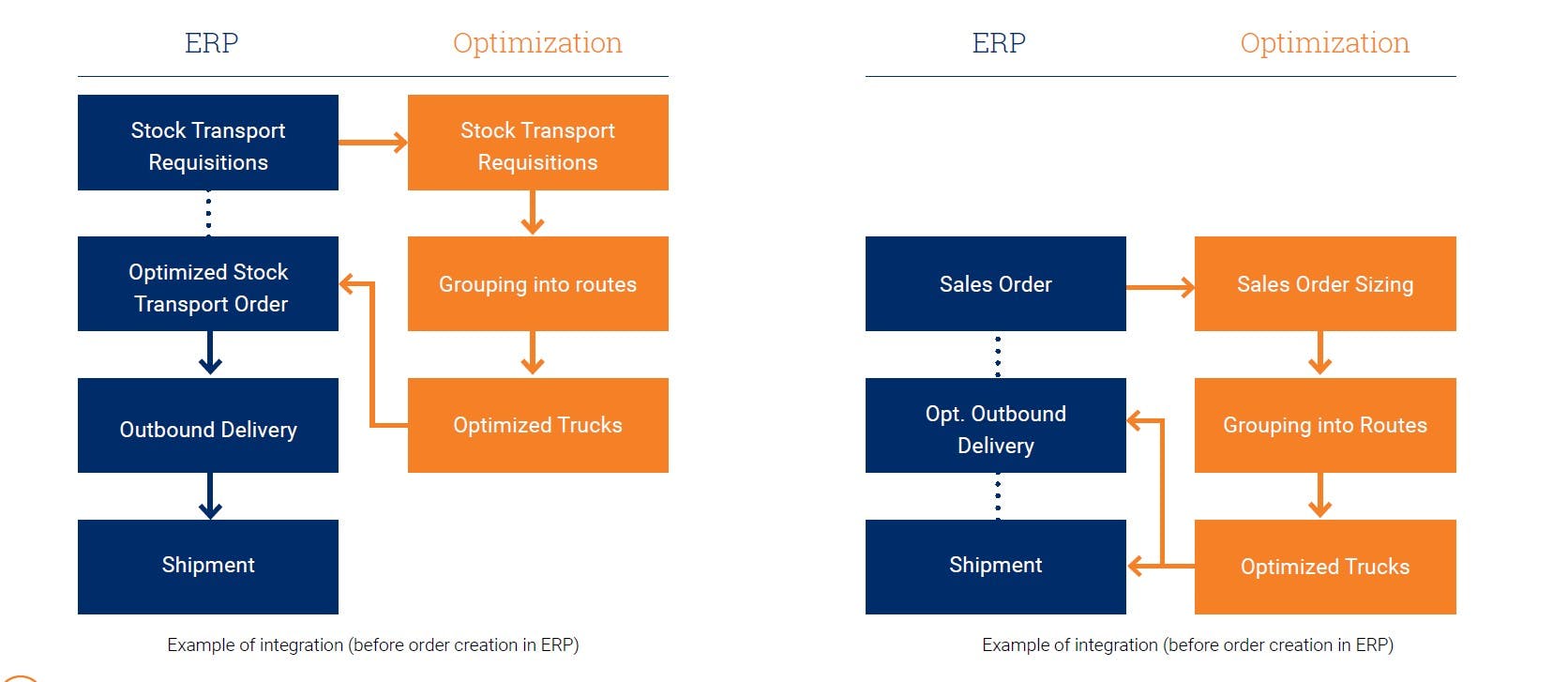

Seamless integration with ERP systems, such as SAP, is critical for end-to-end efficiency.

- Orders defined in the ERP can flow directly into the optimization engine.

- Optimized pallets and routes are executed through a transportation management system (TMS).

- Even for demand-level planning or stock transfers, automated order creation ensures ERP compliance and reduces errors.

By connecting ERP, TMS, and logistics software, producers can streamline operations, reduce integration costs, and improve transportation efficiency.

Customer Success Stories

Global Beer Manufacturer

A leading beer producer serving tens of thousands of customers in a regional market integrated routing optimization, dispatching, and load building into SAP.

• Optimized pallet orientation and trailer loads

• Improved load utilization and route efficiency

• Delivered measurable operational and cost benefits

Global Refreshment Manufacturer

One of the largest refreshment companies in the world implemented an integrated routing and loading model in collaboration with ORTEC and Tilburg University.

• Optimized fleet of trucks and delivery routes

• Achieved $50 million in annual cost savings

• Reduced missed deliveries and fuel consumption

• Increased global customer satisfaction and improved sustainability

Conclusion: Deliver More with Integrated Routing and Loading

- Integrating routing optimization and load optimization allows producers to maximize pallet and trailer utilization, reduce costs, and improve delivery performance.

- Seamless ERP and TMS integration, combined with advanced logistics software and supply chain planning solutions, turns data into actionable improvements and a competitive advantage.

- Next Step: Download our E-Guide "Integrating Routing and Loading for Transportation Efficiency" to explore strategies and practical steps for optimizing your supply chain.

Take the Next Step

Contact us today or request a live demonstration to see how advanced planning and routing shapes the future of efficient, reliable store delivery for retail.