Enhancing Supply Chain Efficiency: The Synergy of Integrated Routing and Loading

Addressing Logistics Challenges for Producers in a Dynamic Market

Producers in North America, Europe, and global manufacturing markets face increasing challenges in managing supply chain operations effectively. From sourcing raw materials to meeting growing service level expectations, the logistics of finished goods have become more complex. These challenges often lead to inefficient transportation results such as high empty truck percentages and underutilized pallets.

Yet within these challenges lies an opportunity to transform operational efficiency. By integrating loading and routing processes, producers can uncover significant value and build a more sustainable and cost effective supply chain. This guide explores the benefits of this integrated approach and how it improves customer satisfaction, reduces carbon emissions, and lowers transportation costs.

This article is a summary of the E-Guide written by Goos Kant, Managing Partner at ORTEC and Professor of Logistic Optimization. Download The Comprehensive Guide to Integrated Routing & Loading for Producers about optimizing transportation for efficiency and sustainability or read the summary below.

Combining Loading & Routing: Two-Step Approach to Optimal Utilization

Step 1: Computing the Size of an Order

An order contains multiple items that must be efficiently stacked on load carriers such as pallets. With detailed logistics data, including item sizes, stacking orientations, and stability rules, an optimization engine can generate pallet configurations that are loading friendly, transport friendly, and unloading friendly. This optimization improves efficiency during loading and positively influences transportation and delivery processes.

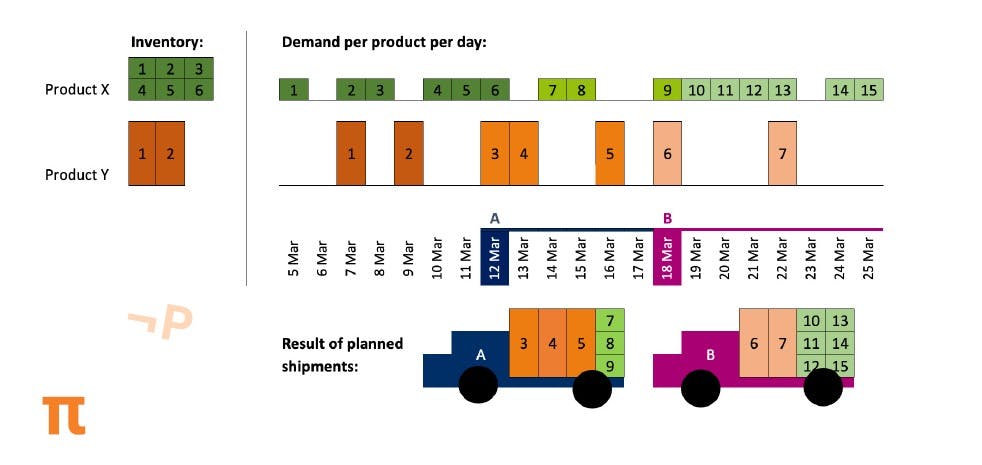

Step 2: Combining Orders to Maximize Capacity Utilization

A 3 dimensional loading optimizer integrated with routing technology creates significantly more efficient loads. By adding details and constraints such as warehouse preferences, driver instructions, and receiver requirements, empty space is minimized and mileage is reduced. Modern transport management software and transportation software can further strengthen this process by aligning trailer space, delivery constraints, and customer requirements.

Goos Kant, Managing Partner at ORTEC and Professor of Logistic Optimization.

"Integrating routing and loading optimization presents a transformative opportunity for manufacturers in the increasingly complex logistics landscape."

Additional Opportunities for Increased Load Utilization

Product Design

Strategic product design can improve space utilization, allowing more items to fit on a pallet layer.

Splitting Orders

Splitting large orders for different delivery destinations can optimize multiple routes and reduce cost.

Fillers

Fast moving products can be added to available space in trailers or pallets for locations with regular deliveries.

Optimization on Demand Level

Forecasting demand and using optimization algorithms ensures the right loading and routing plans align with inventory requirements and customer needs.

How Routing Technology and TMS Software Enhance Integrated Planning

Modern producers increasingly rely on advanced routing technology to streamline delivery operations. When a transportation management system and route optimization software are connected directly to loading and planning workflows, companies can generate delivery routes that maximize truck utilization and reduce empty miles. A TMS system allows planners to review real time constraints, build accurate route plans, and ensure transportation decisions stay aligned with warehouse operations and customer commitments.

The Role of Logistics and Supply Chain Software in Integrated Routing and Loading

Integrated routing and loading benefit significantly from modern logistics software solutions. Logistics management software and supply chain software provide essential visibility, data consistency, and planning accuracy for creating optimal pallet configurations and transportation plans. By synchronizing routing engines, inventory data, and warehouse operations, these platforms help producers automate and streamline the transportation planning workflow across the entire supply chain.

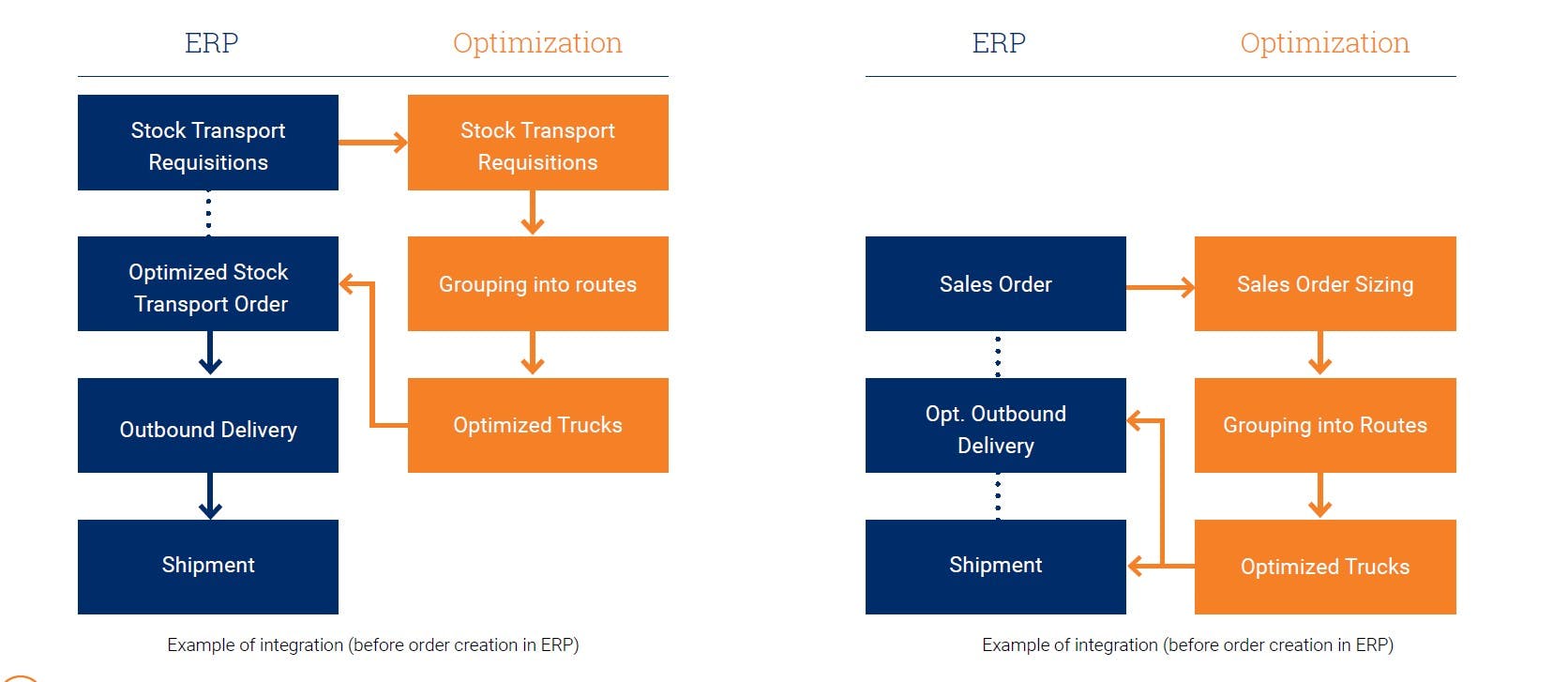

Integrating Process and IT: Streamlining the Supply Chain

To fully benefit from the integrated approach, producers need real time supply chain visibility across the entire planning process. Integration with ERP systems such as SAP, as well as TMS platforms, creates a supply chain control tower model that increases visibility across orders, pallets, routes, and delivery requirements. This connected approach improves decision making, reduces manual workload, and enables automation throughout logistics workflows.

Customer Case Study

Molson Coors Brewing Company implemented an integrated solution within SAP to optimize delivery planning for more than 17,000 customers in Quebec. By using routing and dispatching combined with pallet and load building, the company achieved major improvements in load utilization and route efficiency.

Conclusion: A Path to Enhanced Supply Chain Efficiency

With the global logistics landscape continuing to evolve, the integration of routing and loading offers producers a strong path to improved operational performance. By using advanced technologies, high quality data, and collaboration across supply chain stakeholders, producers can reduce emissions, increase service quality, and improve cost efficiency. This integrated approach also supports sustainable logistics by reducing empty miles and lowering transportation related emissions.

Producers that adopt integrated routing and loading will strengthen competitiveness and advance toward long term sustainability objectives.

Learn more about Integrated Routing and Loading Optimization for Producers

Download the E Guide "Integrating Routing and Loading" to discover how producers improve efficiency, reduce costs, elevate customer service, and meet green initiatives. Or request a demo.