4 Scenarios for Optimized Pallet and Load Building

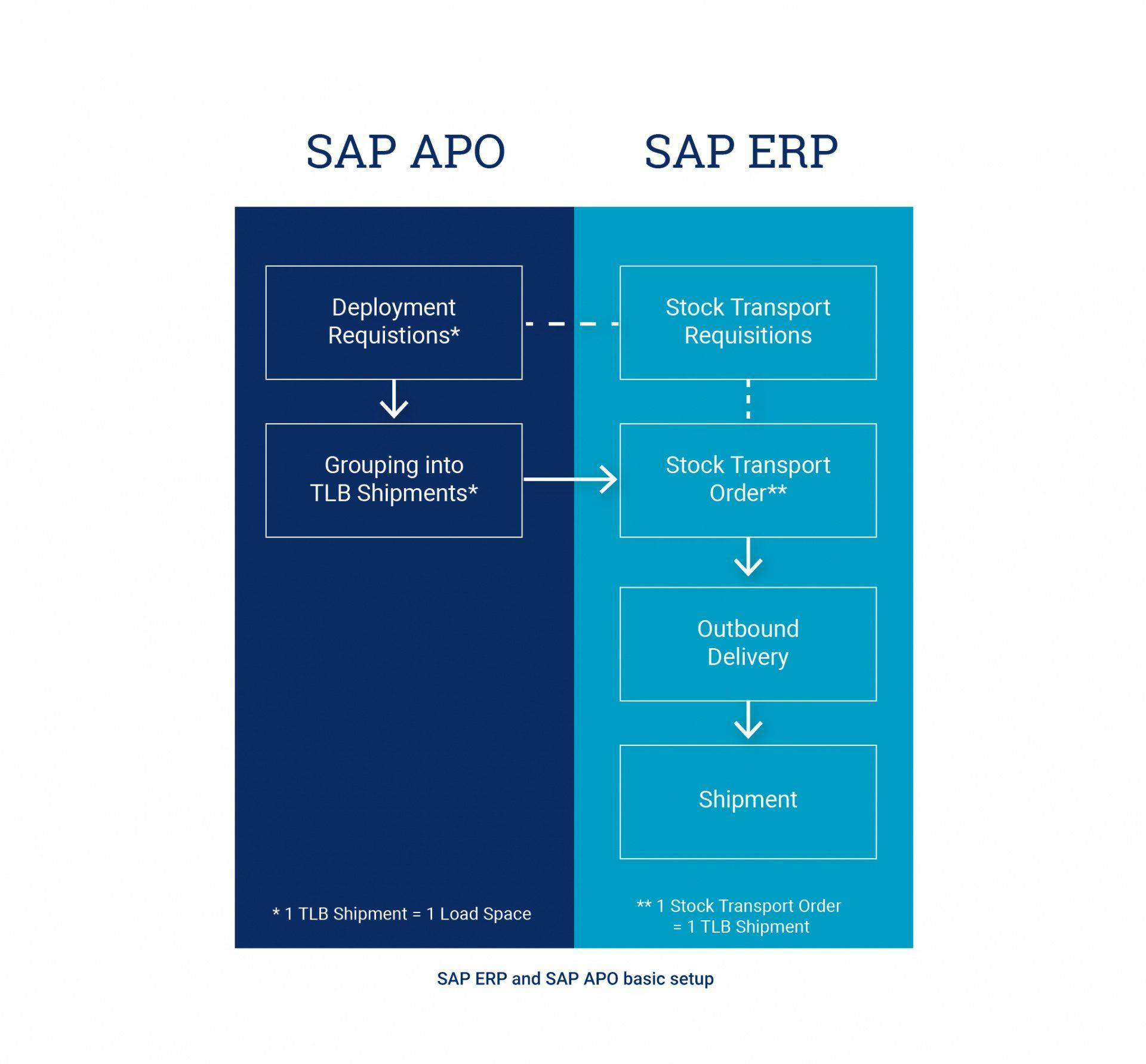

This toolset - shown in figure: SAP ERP and SAP APO basic setup - might be suitable for companies that ship a few truckloads of goods per day. But manufacturing companies that ship dozens or even hundreds of daily truckloads quickly run into limitations. This is because SAP APO and TLB are not equipped to deal with more complex constraints like axle weights, stacking rules, allowed orientations and other business-specific rules. In such cases, you can benefit greatly by using more advanced pallet and load building optimization tools. Even small improvements in truck load fills can result in millions of dollars in savings. In this article, we discuss four scenarios our customers use to lower planning and transportation costs. They achieve this by extending SAP ERP with the advanced load building optimization features in ORTEC for SAP.

Scenario 1: Optimize load building based on Deliveries

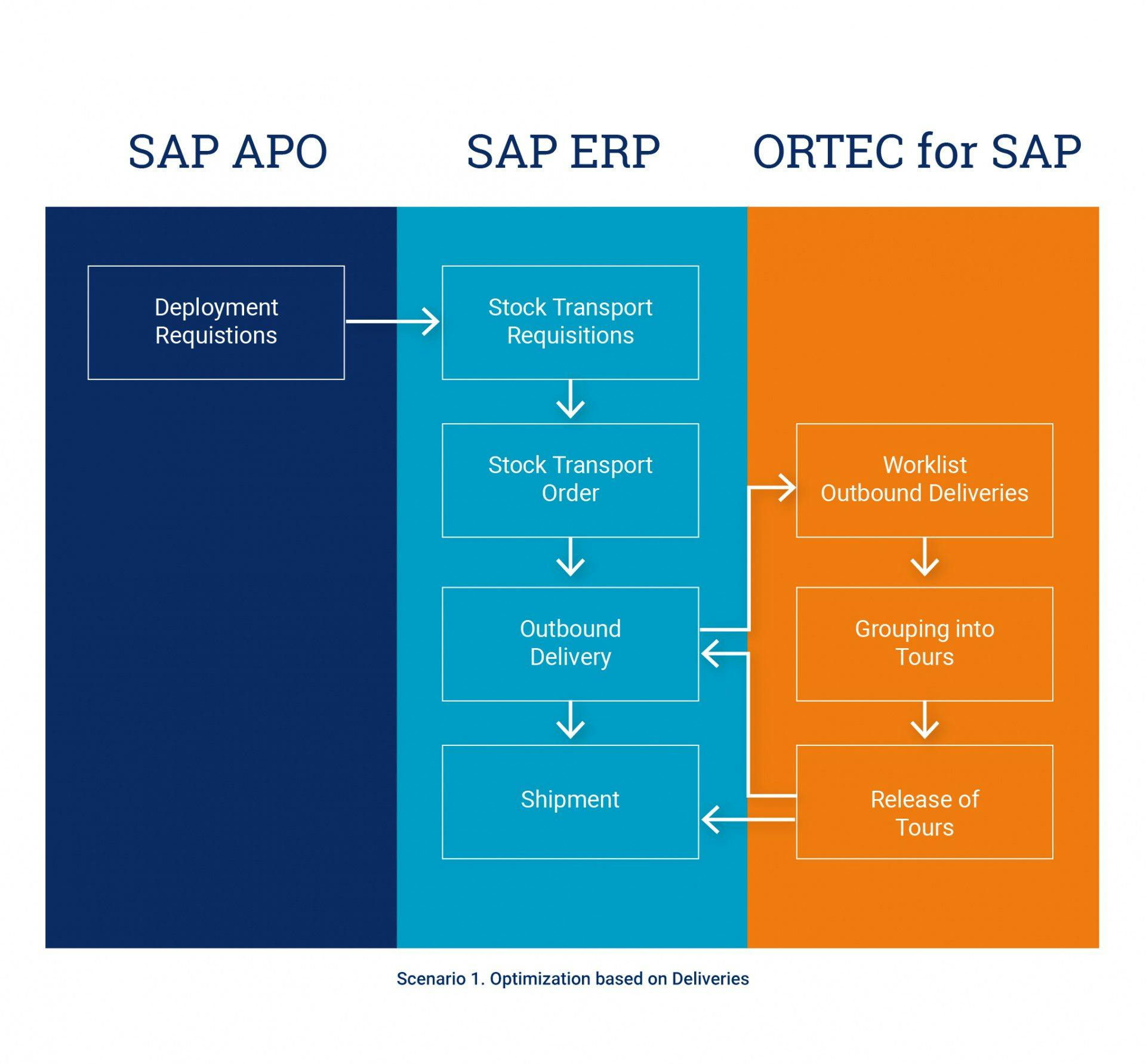

Companies in industries like Manufacturing, Chemicals, and Consumer Packaged Goods must deal with many deliveries every day, so they need to combine them in a clever way to cut costs. Typically, they create “milk runs” to deliver the goods to different customers, and they need to consider optimal pallet building or load building configurations. In an ideal world, trucks would be 100% full when they hit the road. However, most transportation managers know that it’s easy to exceed that threshold and have left-over pallets on the warehouse’s staging area. This creates a lot of problems and leads to frustration for everyone involved: warehouse employees, planners, customer service representatives and customers. So, to avoid this and create a buffer for uncertainty in load calculations, trucks are typically planned to be about 90% full. But that extra 10% can make a huge difference when you have high transport costs.

To achieve savings, our customers combine deliveries in such a way that the minimum number of transportation units (trucks, overseas containers, rail cars or other) is used to fulfil sales orders. Using advanced optimization technology, they can automatically identify optimal delivery splits to increase load fills.

The same method can be applied for deliveries to the same location (where no milk runs, or route optimization is required). For example, deliveries created from Stock Transport Orders to replenish distribution centers. This flow is depicted in figure Scenario 1. Optimization based on Deliveries.

Scenario 2: Optimize load building based on Sales Order Sizing

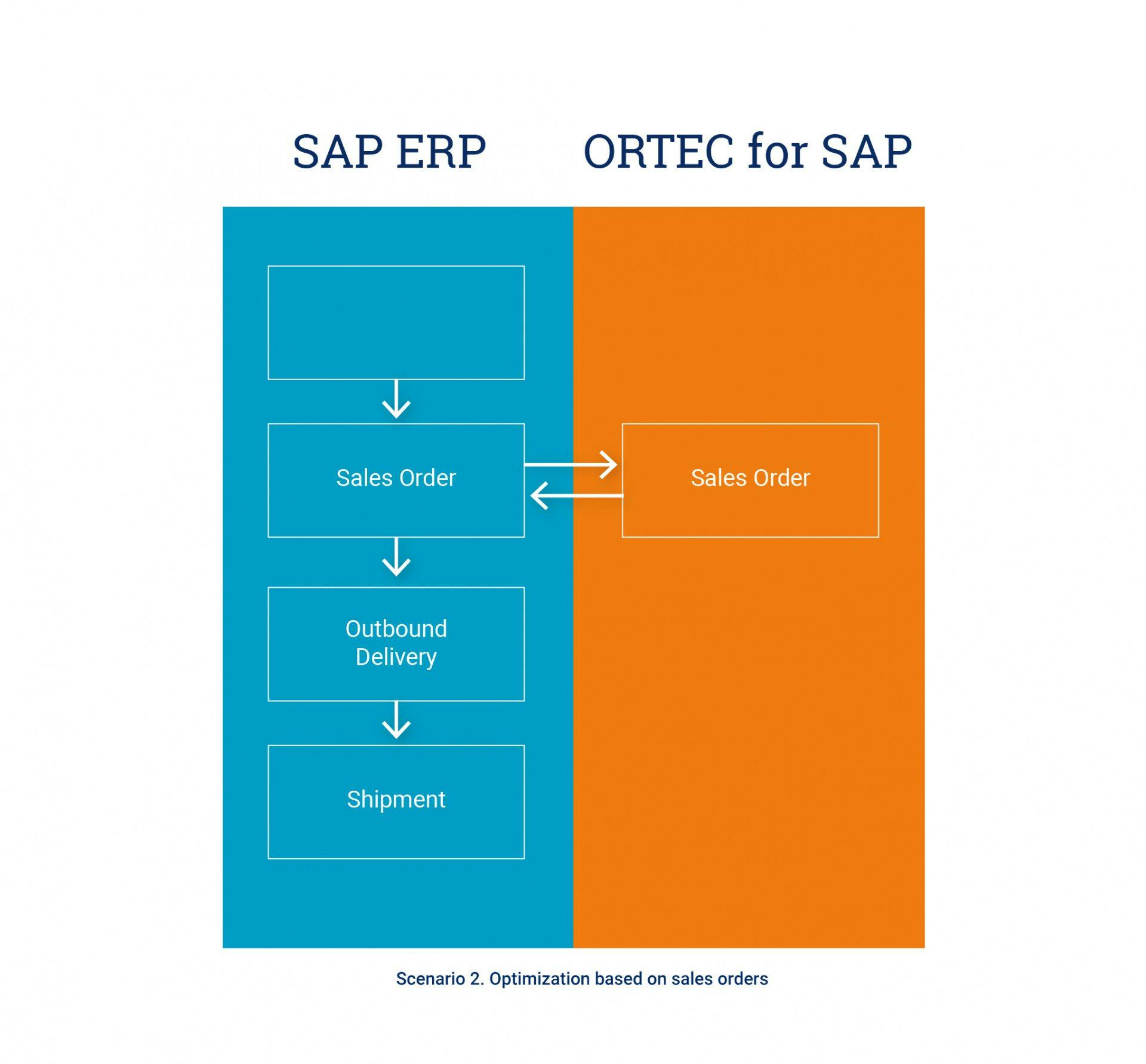

Another approach is optimizing load building based on sales order sizing. Sales orders arrive in various ways:

- Through outbound calling by a customer service representative (CSR)

- By email

- By formal Electronic Data Interchange (EDI) messages interfaced in SAP

Knowing the exact transportation capacity requirements for sales orders allows you to order the right amount of capacity – no more and no less. This helps you avoid unnecessary costs and reduces last minute transportation changes. The flow is depicted in figure: Scenario 2. Optimization based on sales orders

Using advanced optimization modules, like those provided by ORTEC, planners can assess the required transportation capacity (floor spots, pallets, loading meters) per order, as the request comes in. The results of the pallet and loading optimization can be visualized in a 3D display as the Sales Order is entered in SAP ERP. This allows the user to verify if the order can be executed as placed, or if they can adjust the quantities to minimize transportation costs. This scenario is especially useful when there is an agreement in place between the company and their customers, allowing such adjustments to be executed automatically – within an agreed range.

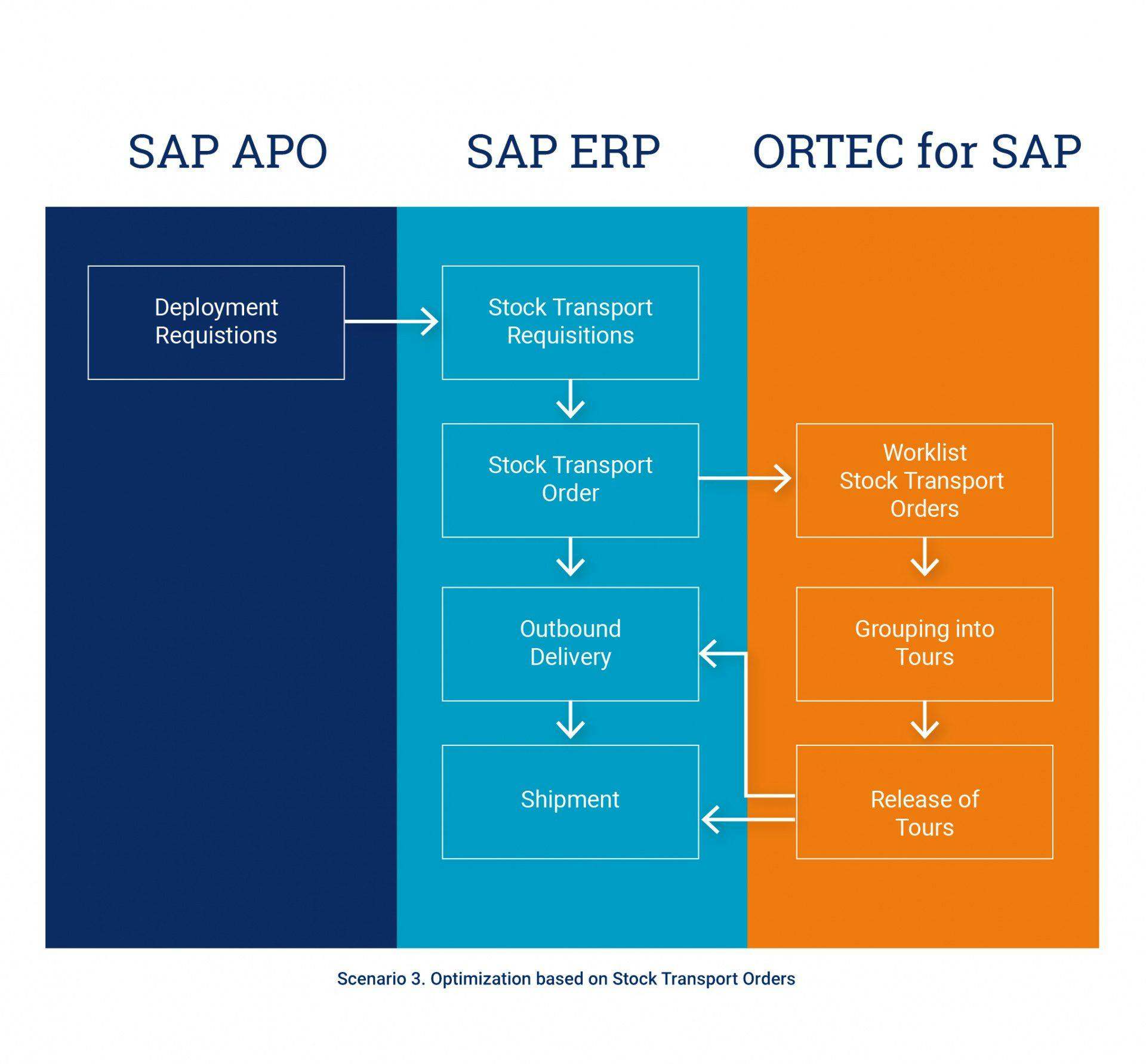

Scenario 3: Optimize load building based on Stock Transport Orders

Planners generate Stock Transport Orders (STOs) in SAP to replenish warehouses/DCs with products that need to be moved to fulfill customer orders. Since these are intra-company movements, it is easy to adjust required product volumes to optimize truck loads and decide when to transport the stock. The flow is shown in figure: Scenario 3. Optimization based on Stock Transport Orders.

For example, Henkel, one of our customers, creates weekly STOs. Each STO has the equivalent of hundreds of pallets worth of product. Instead of planners having to split the pallet loads manually per truck, they use ORTEC’s optimization technology to cut the Stock Transport Orders into outbound deliveries the size of full truck loads automatically. These trucks are then scheduled to move the product on various days during the week.

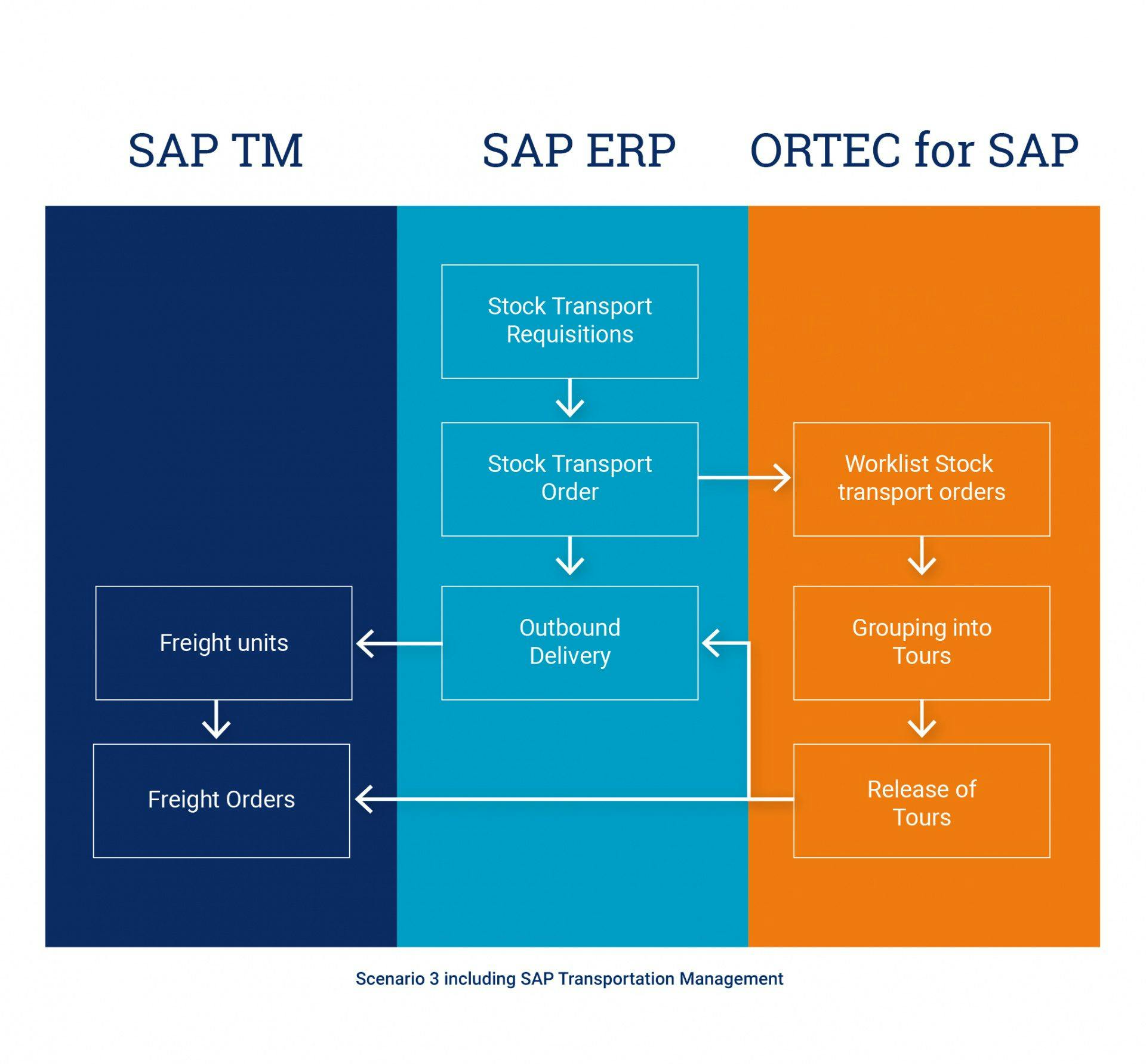

SAP Transportation Management powered by ORTEC

In cases where the company uses SAP Transportation Management the scheme can look a bit different. Instead of Shipments in SAP ERP, they can create Freight Orders in SAP Transportation Management – see flow below. Similar combinations with SAP Transportation Management are viable in the other scenarios as well. SAP APO fits in this scheme as well but has been left out of the picture for clarity. See flow in figure: Scenario 3 including SAP Transportation Management

The optimization opportunities are the same. For instance, instead of using 3 trucks for 3 deliveries, each with a load fill of 60%, you could split one delivery into 2 and use 2 trucks, each with a 90% load fill. With the advanced optimization features in ORTEC for SAP, planners can assess the ideal volume and weight to use in each load combination. Combining heavy and light loads together can also contribute to cost savings.

Layher, a leading provider of scaffolding systems and other construction equipment, is using this method to plan their daily transports and load containers to full capacity. Our SAP-integrated software supports Layher by enabling flexible planning at the line item level, while taking Layher-specific loading rules into account. Transport planners can adjust the loading proposal by adding or removing line items where necessary and can decide to approve planned tours on an individual basis. 3D visualization also allows them to automatically create optimally loaded trucks. The final optimized results are available immediately and can be easily communicated and shared.

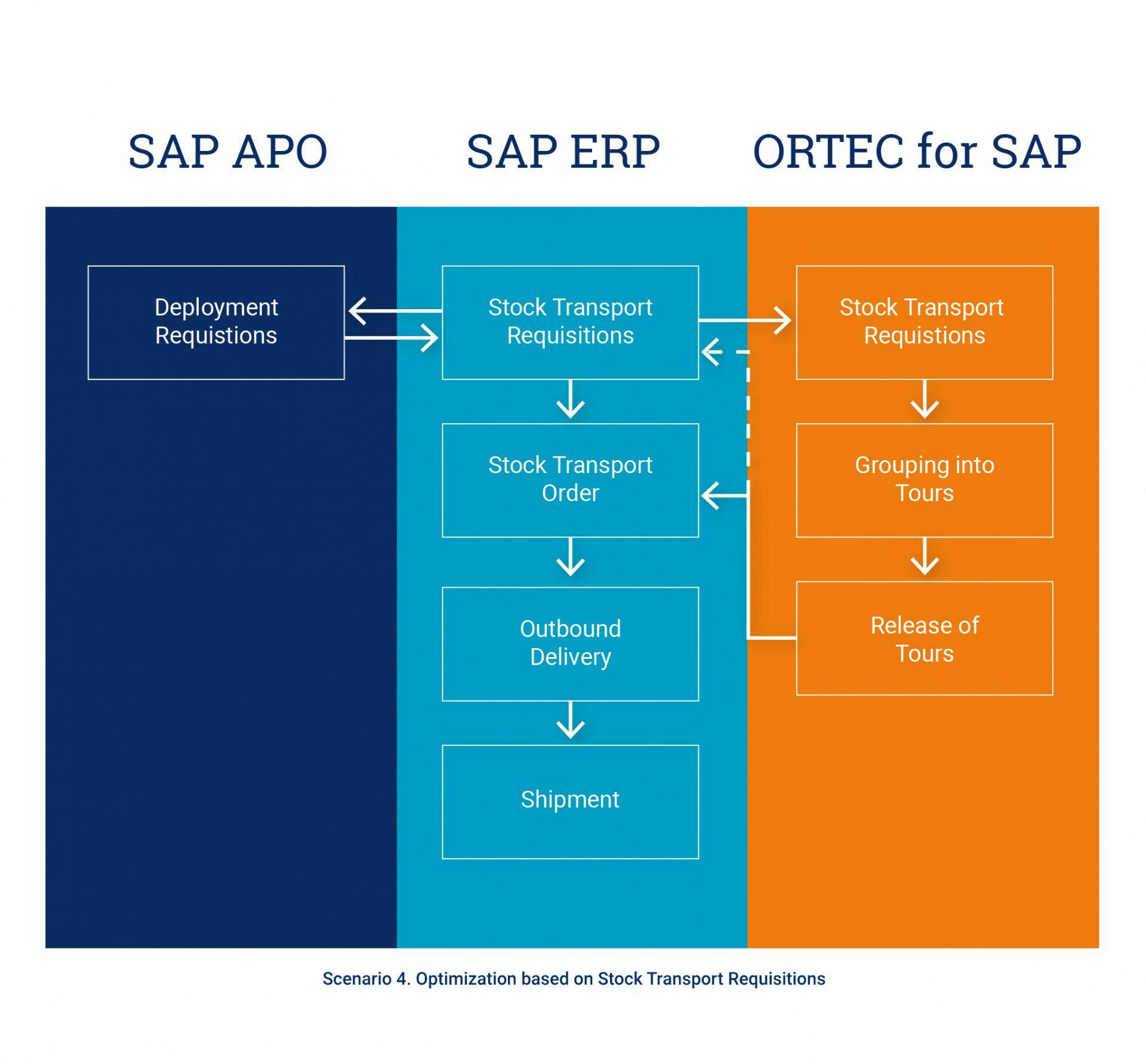

Scenario 4: Optimize load building based on Deployment Requisitions / Stock Transport Requisitions

A potential problem with creating STOs first and then running advanced optimization is that the product can be locked too far in advance, creating artificial shortages. For example, if you generate an STO for a high priority order locking stock that needs to be delivered in two-week’s time, you’re not able to use that product for other earlier deliveries.

Instead of using STOs as input for load building optimization, as described in the previous scenario, you can use stock transport requisitions (STR) based on deployment requisitions (DepRecs). Deployment requisitions are requests that come from a warehouse when they need inventory to service customers or replenish stock levels. When you use STRs as the input for optimization, you will get optimized transport orders (STO) as output. This means you will assign the right amount of product to the right shipment from the start. You don’t only get an optimal load building configuration, but can also schedule deliveries and shipments automatically, as you’ll have the right amount of stock on hand. See flow in figure: Scenario 4. Optimization based on Stock Transport Requisitions

When you optimize early in the process, you get an overview of everything that needs to be transported. This makes it easy to identify if there are shortages as well. In such cases, you can either let the planner decide who gets what or set up some rules to divide and assign available products automatically. The advantage of using optimization before assigning STOs is that you remove tedious activities in SAP. It means you can avoid manually removing STOs from SAP and reassigning stock manually. The exact setup depends on the way SAP is configured and used at your company.

The benefits of advanced optimization for SAP Transportation Management

As a rule of thumb, fewer trucks on the road means lower costs. To use your transport capacity in the best possible way, use optimization during the early stages of the planning process. Companies that spend $50-100 million or more on transportation per year can save between 5-10% of these costs by using the scenarios above. Although the process we describe is for outbound activities, a similar process can be created for inbound flows. In both cases, it pays off to size orders and get optimal truck loads as early as possible to optimize your distribution costs.

Contact us to learn more about ORTEC for SAP, a market-leading add-on for SAP ERP that increases returns on SAP Transportation Management.

Optimize Your Logistics and Enhance the Power of Your SAP Solution. Contact Us Now.

Don't let inefficient loading and routing hinder your manufacturing success. ORTEC’s certified integration to your SAP environment unlocks a new level of logistical excellence with 3-dimensional load optimization and dynamic vehicle route scheduling.