Innovative Solutions for Energy Downstream Distribution

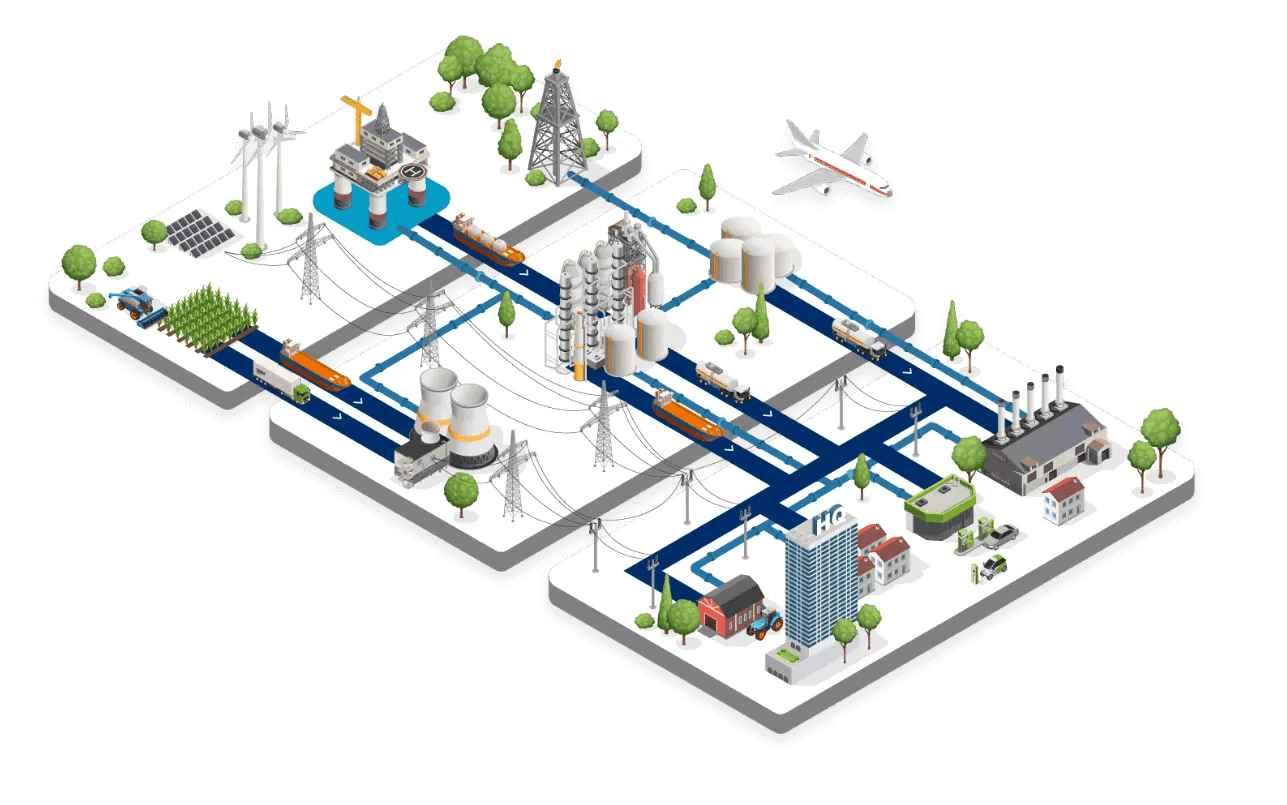

Reading time: 7 minutesGetting products to end customers efficiently is one of the primary challenges in the energy downstream distribution sector. Data analytics is important in all phases of energy delivery, from optimizing inventory routing and forecasting to order planning and implementing smart applications or workforce scheduling. In this interview, we explore the opportunities this presents and the solutions ORTEC has developed.

An interview with ORTEC's Ad Peekstok, Principal Solutions Architect - Inventory Routing, and Laura Simons, Solutions Architect - Route Optimization.

Overview

- What is the impact of data analytics on energy delivery?

- How do algorithms optimize transport planning in the energy sector?

- Why is on-time delivery crucial in inventory routing?

- How does ORTEC balance customer satisfaction with efficiency?

- How are transportation costs reduced per gallon of fuel?

- What are the steps in ORTEC’s optimization process?

- How does ORTEC offer freedom within constraints for planners?

- How can Inventory Routing transform a planner’s role?

What is the impact of data analytics on energy delivery?

Ad Peekstok (principal solutions architect at ORTEC Inventory Routing) and Laura Simons (solutions architect for Route Optimization) help companies in the energy sector optimize their transportation planning on behalf of ORTEC. This work involves aspects like timing, ensuring just enough stock is available at the right time, and finding the right balance between customer satisfaction and efficiency. “Every restriction makes the problem more complex, and our inventory routing process factors in more restrictions than a human ever could,” say Peekstok and Simons. They explain how ORTEC's approach is effective, observing: “We can shave multiple percentages from transportation costs while minimizing the number of product run-outs.”

How do algorithms optimize transportation planning in the energy sector?

Faltering supply chains, geopolitical shifts, and a very tight labor market make the need for proper transportation planning and control can’t be underestimated. This urgency is particularly felt in the energy sector, where a high-value product is transported. Ad Peekstok says: “Our customers tell us that they're struggling to find all the drivers they need. At the same time, trucks are an expensive part of a business, so you want to use them effectively. This makes efficient planning even more critical.”

“Algorithm and optimization have suddenly become words that people know ,” add Laura Simons, “perhaps because the media has paid a lot of attention to the fact that optimization can save you money.”

Algorithm and optimization have suddenly become words that people know, perhaps because the media has paid a lot of attention to the fact that optimization can save you money.

Why is on-time delivery crucial in inventory routing?

“Inventory Routing is a specific form of routing and planning,” begins Peekstok, explaining how he and colleague Simons support companies. “You need to get to the end customer on time so that they have enough product for their business. It’s about striking a balance: not too early, which results in higher transportation costs, and not too late, as this would leave your customer without their much-needed products. ORTEC provides inventory routing software for LPG distributors, fuels distributors, manufacturing, chemicals, and industrial gases. While the fuel and LPG businesses are miles apart and involve challenges of an entirely different nature, ORTEC Inventory Routing can meet them all. We are also involved in the gas cylinders business, especially with customers we already have in bulk gas."

“The crux of the matter is that you deliver on time.” Simons elaborates: “Delivering too early means that you’ll need to pay a second visit to the customer. After all, going sooner means you’ll be able to deliver less product.”

Route optimization is key to maintaining customer satisfaction and operational efficiency.

How does ORTEC balance customer satisfaction with efficiency?

Simons addresses this balance, saying: “Route optimization balances customer satisfaction and efficiency. Customer satisfaction comes down to ensuring that products do not run out, adhering to the strict planning guidelines in customer contracts, and delivering products at the agreed-upon time. On the other hand, you want to minimize the distance between orders. It’s essentially a geographical balancing act that we solve with our customers, based on their notion of a ‘good plan’ given the circumstances.”

Peekstok adds, “In fuels distribution, and particularly in the LPG business, what constitutes a good plan could change between seasons. For example, LPG is mainly used for heating homes, so in summertime we have a surplus of trucks and in wintertime they're in short supply. Given those constraints, what is a good plan? In the summer, you want to retain your drivers, and in the winter, you at least want to supply your most important customers, all the while focusing on cost and minimizing the number of product run-outs.”

How are transportation costs reduced per gallon of fuel?

“Timely delivery is linked to one of ORTEC's unique selling points in downstream distribution,” says Peekstok. “Our competitors usually create an order when the product drops below a certain level in the tank. ORTEC’s inventory routing software, however, analyzes the consumption and predicts when the next delivery is required. Instead of being reactive, you proactively create an order, which means you know well in advance when you’ll have to serve which customer. This, in turn, lets you combine customers, cutting down on trips and reducing transportation costs. Combining two orders that are close together lowers the costs per gallon of transported fuel, which is where you make a profit.

"Take gas stations, for example, which sell different products bought at different rates. Demand for premium products is typically lower than for standard levels. The standard grades will usually be the first to reach what's known as the safety stock level—the level in the tank that constitutes the ideal balance between the risk of running out and undersized order volumes. We predict that moment and then look at which other products to deliver simultaneously. This information results in an order tailored to the available truck layouts, allowing for a full truckload with the right product mix at the right time."

What are the steps in ORTEC’s optimization process?

It’s a step-by-step process, Peekstok emphasizes. “It all begins with the forecast, which means you need the customer’s historical data in order. Then, you can use the data to predict future demand and determine when you need to be at the customer site for delivery. That outcome is step one: a large set of orders that need to be delivered at a certain time, between a specific start and end date. That is the input for the route planning software for oil and gas, which generates the best possible schedule based on the available trucks, required travel time, maximum axle weights, etc. Naturally, we align with the customer to define what ‘best possible’ means for them, striking a balance between various interests, requirements, and restrictions.”

“Optimization is usually the second step in this industry,” says Simons, adding, “While optimization is the ultimate goal, you can’t get there without a solid foundation, like a well-organized data infrastructure. What you do also depends on the customer’s knowledge level, as well as their customers, planners, and drivers.”

That’s what sets ORTEC's energy projects apart, Simons believes: “Together with our customers we work on the incremental improvement process. We align with our customers on their needs, use our expertise in the field, and work together on the best way forward.”

While customers may hope for a quick solution, effective planning is a detailed, step-by-step journey.

How does ORTEC offer freedom within constraints for planners?

“At ORTEC, we translate the underlying math that goes into routing into a product planners can use,” says Simons. “We know our customers inside out. Some have been with us for forty years, and we’ve been involved in routing in the oil and gas world for nearly twenty-five years. One of the strengths of our planning is that it allows for a range of delivery dates, rather than one single date, after which our optimization process determines which day is best. There’s a lot of freedom to make good choices. You could never achieve the same results with manual planning, as the effect of the choices you make is not immediately visible.”

Peekstok adds, “You’re dealing with sets of trucks and drivers who are available for a certain number of hours. Then you have to factor in maximum axle weights, various time windows—all those constraints must be balanced to create an efficient plan that actually saves costs. Our software for optimizing replenishment schedules factors in more constraints than a person ever could. The tool is unique in predicting when you need to be at which customer with what mix of products. While you can predict when a particular product will reach its safety stock, not every product reaches that level simultaneously. If considered individually, you’d have to visit the same customer multiple times to deliver multiple different products, resulting in numerous trips. ORTEC Inventory Routing predicts which product reaches the safety stock level first and immediately looks at which other products can also be delivered at the same time, given the available trucks. None of our competitors offer the same feature. Combined with our route optimization, I dare say we are the best in the world.”

Simons concludes, “Because we factor in more than 30 constraints, every new constraint adds a significant layer of complexity. Break rules, fuel terminal opening times, products available at the terminal, customer opening times, truck type, driver certification—all these factors are automatically checked in a fraction of the time it would take a planner. The fact that our product combines routing, data management, order forecasting, and resource management makes it truly special. It was designed this way for a good reason: everything is interconnected.”

Combining nearby orders significantly cuts down the transportation costs per gallon, enhancing profitability.

How can Inventory Routing transform a planner’s role?

The introduction of ORTEC Inventory Routing can change the role of planners, Peekstok has noticed. “Before using Inventory Routing, planners would make a general plan, and the drivers together with the terminal staff would figure out the details. That planning approach relies heavily on knowledge that only drivers have. Our solution is often purchased as a control tower system that aggregates everything. The knowledge of the drivers is centralized in the system; the planner verifies the data in the system and then handles the forecasting, the order generation, and the routing. By making planners responsible for the process, the system gives them a more proactive role. Simultaneously, it also means it takes time to generate an actionable, cost-saving plan at the touch of a button. To get there, change management is needed.”

Maximizing the benefits of ORTEC’s software requires patience, Peekstok and Simons acknowledge. “And it’s essential to align goals internally in advance,” Simons recommends.

“It’s not a choice we can make for our customers.” Peekstok adds, “We can advise and clarify the impact of certain choices. But there is a change management aspect that customers need to be aware of, and we address that too. The pure implementation of ORTEC Inventory Routing is not the most complicated part. The challenge lies in reaching a decision with all parties involved, integrating all systems, and getting accustomed to a different way of working. All of that influences the end result. The key is to start not too big but tackle things step by step.”

Simons concludes, “And every step we take together has added value.”

About Ad Peekstock

With over fifteen years at ORTEC and more than a decade in the oil and gas sector from Australia to America, Ad Peekstok excels as the Principal Solutions Architect of ORTEC Inventory Routing. He bridges the gap between industry, IT, and people.

About Laura Simons

Since joining ORTEC in 2017, Laura Simons has transitioned from an implementation consultant to a solutions architect, focusing on route optimization. She works on diverse projects across industries including the energy sector, largely in the US and European gas sector.

Explore Our Downstream Solutions

Discover how ORTEC's cutting-edge solutions can optimize your downstream distribution processes.

Ready to Get Started?

Do you want to learn more about ORTEC’s Energy Optimization solutions and learn about our latest insights? Contact us and let's start a conversation.