Introduction to the Food and Beverage Supply Chain

The food and beverage supply chain is a complex network that ensures products reach consumers with quality and efficiency. From sourcing raw materials to delivering finished goods, the supply chain involves multiple stages that each play a critical role. Recent advancements in technology and shifting consumer expectations have made agility and transparency indispensable. This guide serves as your definitive resource for understanding and optimizing your food and beverage supply chain.

For those looking to deepen their understanding of these dynamics, our Comprehensive Guide to Food and Beverage Distribution offers valuable insights and strategies.

Key Components of the Food and Beverage Supply Chain

Procurement and Sourcing

Procurement is the starting point of the food supply chain, involving identifying reliable suppliers and negotiating terms. It's imperative to focus on sustainable sourcing practices, ensuring the continuity of supply while respecting environmental and social standards.

- Sustainable Sourcing: Adopt practices that reduce environmental impact and support ethical labor conditions.

- Supplier Negotiations: Build strong partnerships with suppliers to secure consistent quality and favorable pricing.

Production and Manufacturing

Efficient production processes ensure that goods are made to standards and are prepared for timely distribution.

- Lean Manufacturing: Use principles that streamline production, reduce waste, and optimize operations.

- Technology Integration: Implement IoT and automation to enhance production efficiency and quality control.

Inventory Management

Managing inventory effectively reduces waste and meets consumer demand. This includes leveraging predictive analytics to anticipate market fluctuations and optimize stock levels.

- Perishable Goods Management: Implement strategies for handling goods with limited shelf life to minimize losses.

- Inventory Optimization Tools: Use software to automate replenishment and balance supply and demand efficiently.

Distribution and Logistics

Efficient distribution and logistics are vital for minimizing costs and ensuring timely deliveries.

Efficient Transportation Networks

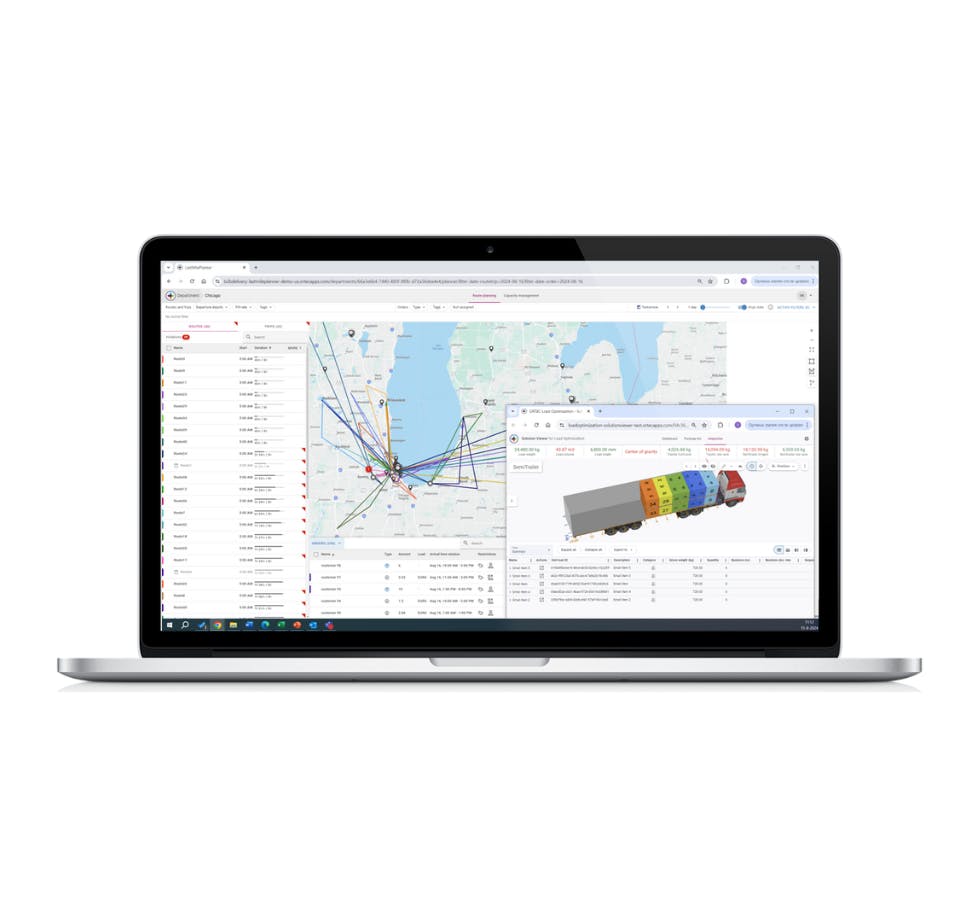

Route optimization and load management are essential for minimizing fuel consumption and meeting delivery windows.

- AI-Powered Route Optimization: Leverage advanced algorithms to refine delivery schedules and reduce transit times.

- Load Building: Optimize vehicle loads to maximize efficiency and reduce trips.

Cold Chain Management

Maintaining the quality of perishable products during storage and distribution is crucial. Advanced cold chain technologies ensure temperature control and product integrity.

- Temperature Monitoring: Utilize IoT solutions to monitor conditions throughout the transport process.

- Refrigerated Transportation: Invest in modern refrigerated units to guarantee quality and safety.

Technology and Innovation in Supply Chains

As technology evolves, it presents opportunities to optimize various aspects of the food and beverage supply chain.

AI and Machine Learning

These technologies empower businesses to make data-driven decisions and predict future trends with high accuracy.

- Predictive Analytics: Use machine learning models to forecast demand and adjust strategies accordingly.

- Dynamic Routing: Adapt delivery routes in real time to address traffic conditions and urgent customer needs.

IoT and Automation

IoT devices provide real-time data that enhances visibility and control throughout the supply chain.

- Real-Time Tracking Systems: Keep track of shipments for assurance and accountability.

- Automation in Warehousing: Streamline operations and reduce manual errors with automated systems.

Sustainability and Compliance

Ensuring sustainability and compliance with regulations is both a moral and business necessity.

Sustainable Practices

Incorporating sustainability reduces environmental impact and meets growing consumer expectations for eco-friendly products.

- Eco-friendly Packaging: Implement biodegradable materials to reduce plastic waste.

- Energy-efficient Processes: Optimize processes to minimize energy consumption.

Regulatory Requirements

Staying compliant with food safety laws and regulations is crucial for maintaining brand reputation and customer trust.

- Food Safety Standards: Regular audits and adherence to standards ensure safety and quality.

- Compliance Monitoring Tools: Use technology to track and maintain compliance effortlessly.

Advantages of Optimized Supply Chains

Optimizing the supply chain translates to numerous benefits, from cost savings to enhanced customer satisfaction.

Efficiency and Cost Reduction

Streamlining operations reduces operational costs, allowing savings to be reinvested into the business.

- Resource Optimization: Utilize resources more effectively to reduce waste and enhance productivity.

- Cost Management Strategies: Implement strategies that lower expenses across the supply chain.

Enhanced Customer Satisfaction

Prompt deliveries and improved service reliability boost customer loyalty and drive repeat business.

- Improved Service Quality: Focus on meeting customer expectations consistently.

- Customer Relationship Management: Use CRM tools to understand and meet customer needs better.

Step-by-Step Guide to Optimizing Your Supply Chain

For businesses looking to optimize their supply chains, implementing a structured approach is essential. Here's a step-by-step guide tailored to ensure seamless integration and maximum efficiency:

Pre-Operation Strategies

- Demand Forecasting: Use predictive analytics to assess future demand and plan accordingly. This minimizes surplus and shortage issues.

- Territory and Route Planning: Define territories and master routes to streamline delivery and reduce unnecessary travel.

- Supplier Collaboration: Establish open lines of communication with suppliers to enhance coordination and response times.

During Operation

- Real-Time Monitoring: Utilize IoT and GPS tracking to oversee shipments, ensuring timely deliveries and addressing issues as they arise.

- Dynamic Adjustments: Adapt logistics plans in real-time based on traffic patterns, weather conditions, and urgent requirements.

- Control Tower Operations: Implement an oversight system to coordinate cross-functional tasks and monitor performance metrics.

Post-Operation Improvement

- Performance Analysis: Analyze data from completed operations to identify inefficiencies and areas for improvement.

- Feedback Loops: Gather feedback from stakeholders to continuously refine processes and enhance service quality.

- Continuous Training: Educate staff on new technologies and practices to maintain high performance and innovation.

Conclusion

Optimizing the food and beverage supply chain is no longer a mere option but a necessity for businesses aiming to remain competitive in a rapidly changing market. By embracing technology and sustainable practices, companies can deliver greater value, reduce costs, and improve customer satisfaction. Use this guide as your roadmap to unlock new efficiencies and stay ahead of industry challenges.

Continue your learning journey. Download our in-depth guide on supply chain optimization for the food and beverage industry.