The quick route to global S&OP in multinational supply chains

When sales & operations planning processes are performed at the local level, global or regional oversight and optimization often falls short. ORTEC offers solutions to gain control over cross-border demand, supply, production, and distribution, ensuring a streamlined and cohesive S&OP approach.

_______

Industries:

Manufacturing, Retail, Wholesale

Business areas:

Planning & Forecasting

What is S&OP orchestration?

FMCG companies (or companies with similar siloed supply chains) need to routinely balance demand and supply across their vast network, which consists of various customer types and numerous distribution points, plants, and suppliers. Enhancing financial key performance indicators (KPIs) and advancing other performance measures is an intricate and ongoing challenge due to the plethora of SKUs, complex demand structures, and numerous production and warehouse locations. While most industry players are adept at planning within isolated operating units, like a national branch, many fail to unlock the potential of viewing the entire multinational supply chain as a cohesive network, optimizing production and logistics capabilities collectively.

Many FMCG companies have experienced periods during which they have not emphasized leveraging the synergies in a comprehensive, multinational network through a unified S&OP process. This can occur during intense merger and acquisition phases with incomplete integration of acquired entities or significant changes on either the demand or supply planning side. During such times, companies often perceive establishing a full S&OP system as too cumbersome, time-consuming, and costly. The result is clear: these companies trail behind peers who have adopted effective tactical planning strategies.

Four hallmark barriers to international control

Through the nature of their growth, most multinational companies are created from self-organizing local entities learning to work together, and at some point encounter one or more of four distinct hallmark barriers:

- Scattered S&OP tooling landscape on local level, no global/regional layer exists above local tools. Oftentimes completely different S&OP software, definitions and processes are used.

- Lack of functional Supply Chain visibility on global/regional level, with planners spending excessive time gathering data.

- Fragmented data stored in local systems only, requiring manual consolidation.

- Financialization of global/regional plans is non-existantexistent. Supply Plans are only volume based. They lack the insight for bottom-line financial decision making.

How to achieve orchestration without global systems overhaul

ORTEC has demonstrated that the implementation of “one” overall sales and operations planning process, based on a common tool set, can be successfully achieved with only moderate investment and without the typical drawbacks that often come along with system implementation. Instead of globally implementing complex off-the-shelf S&OP software packages, we provide an approach that helps FMCG companies to achieve results quickly, in a collaborative effort, and with excellent ROI.

How do you approach S&OP Orchestration?

ORTEC combines the expertise of business process consultants with state-of-the-art software, AI, and optimization techniques to offer comprehensive solutions. Here are key points about our approach and solutions:

- Full coverage of the software lifecycle, including planning, building, implementation and maintenance, to ensure comprehensive solutions.

- Deliver substantial long-term value by aligning solutions strategically with the customer’s global and local IT strategies.

- Leverage tried-and-true components to craft applications tailored to each company’s unique needs.

- Employ an agile methodology that ensures our experts work closely with the customer’s users from the outset.

- Deliver solutions rapidly (Minimum Viable Product - MVP) and enable collaborative evolution with the customer’s team.

- Partner with company data specialists to guarantee data availability and integrity as the solution matures.

Our approach ensures substantial long-term benefits through innovative, customized solutions that evolve collaboratively with clients, leveraging data effectively.

Heineken: Orchestrating Billions of Beers

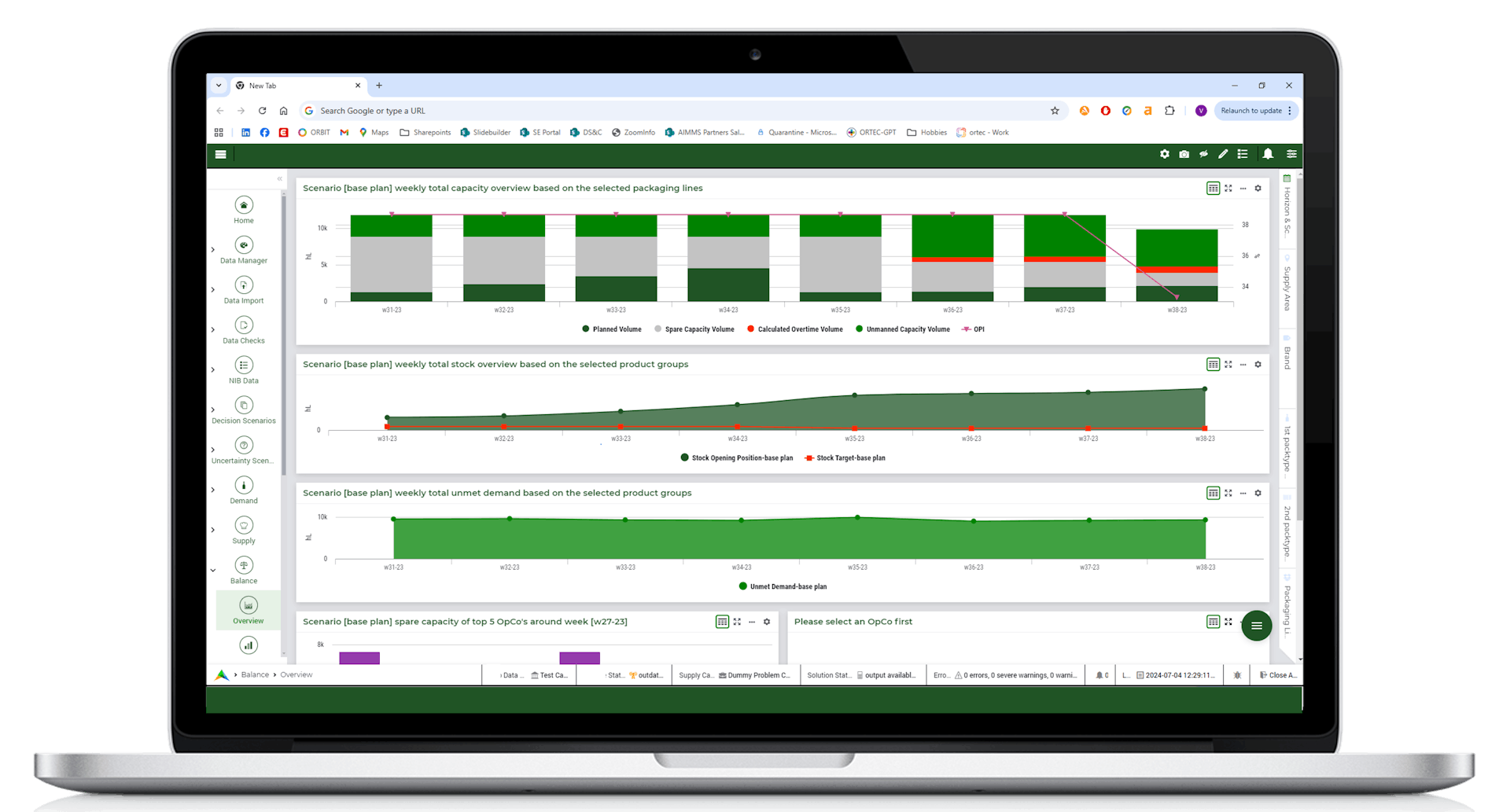

ORTEC has developed a customized tool set for the HEINEKEN Group to run Supply and Operations Planning (S&OP), streamlining their planning processes across all local operational companies. These tools enable HEINEKEN to effectively balance the demand for thousands of SKUs with supply across its extensive network of breweries and distribution centers. The optimization capabilities and advanced analytics provide HEINEKEN's decision-makers with the means to boost revenue, improve margins, and utilize resources effectively, leading to increased profitability.

The S&OP suite enhances existing tools used by their operational companies, such as Blue Yonder S&OP, which were previously limited to local operations. The suite includes an S&OP orchestration tool and a Supply Planning tool that integrates resources and facilities throughout the HEINEKEN network.

Local planning systems demand plans into the S&OP tool, which enriches them with additional data, such as risks and opportunities. The Supply Planning tool calculates supply plans and integrates them with the S&OP tool, offering extensive scenario analysis capabilities. Plans are further refined with short P&L versions to aid decision-making.

Jasper Blaas - Planning Capability Manager HEINEKEN

"That’s why we rely on ORTEC - and not just for their tools, but also for their ability to help us define our challenges effectively."

Simultaneously, a central data lake has been expanded to facilitate seamless data integration across HEINEKEN's entire data landscape. Building on the toolset on Group-level, a local S&OP tool version has been developed and deployed to those operational companies which had previously lacked a robust software solution.

HEINEKEN now runs a consistent monthly S&OP cycle, where:

- All relevant data and planning outputs are directly accessible from the tool.

- Planning collaboration between local operational units and Group functions is seamless.

- High responsiveness to shifting market conditions or internal changes is maintained.

Tools were developed in close collaboration with HEINEKEN teams, ensuring fast delivery of MVPs with active involvement from key users. This tailored approach has been instrumental in securing data availability and aligning stakeholders both at central and local levels. MVPs for S&OP and supply planning have been continuously refined with each release, and the development journey continues.