Control Tower for Supply Chains

Control Tower for Supply Chains

What is a Control Tower for Supply Chains?

A control tower for supply chains is a central hub with the required technology, organization and processes to capture and use transportation data to provide enhanced visibility for short- and long-term decision-making aligned with strategic objectives. When you add optimization functionality to a control tower, better decisions and improved efficiency and/or service are within reach.

Why optimize the supply chain with a Control Tower?

Control towers in general support the following essential needs for managing supply chains:

- Provide end-to-end supply chain visibility

- Respond and adapt to supply chain disruptions

- Deliver multi-tier process orchestration and supply chain collaboration

- Maximize predictive decision-making and dynamic supply chain execution

Motives for using a control tower vary among companies and industries include:

- Centralized decision-making in CPG

- Supply chain collaboration in manufacturing

- Transparency in retail distribution

How do you optimize the supply chain with a Control Tower?

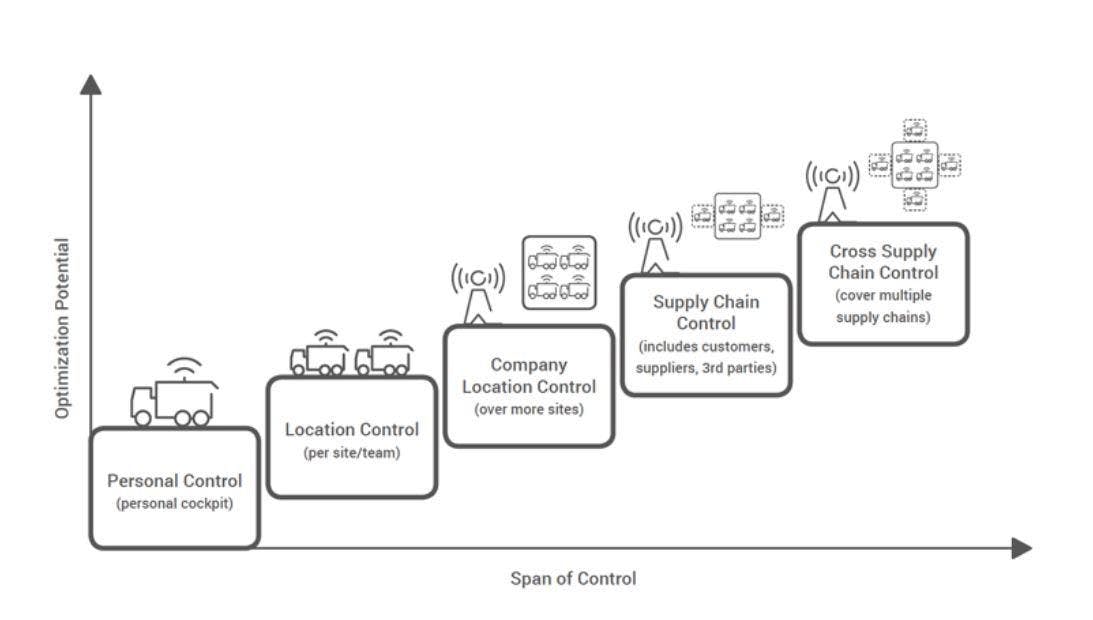

In transportation, a control tower provides visibility and collaboration at different levels. The main application areas for control tower solutions are found at levels 3, 4, or 5.

- Personal Level: Using the control tower by only an individual within a company is a natural starting point, but offers limited benefits.

- Team Level: Giving a location or division access to a control tower allows synergy for transportation planning within a team, such as offering more combinations of inbound and outbound or pickup and delivery.

- Company Level: Implementing a control tower to provide one central platform within the company for optimization and visibility at different locations means complete optimization across all transportation divisions within the company, e.g. over multiple depots, or by exchanging employees across teams.

- Supply Chain Level: Deploying the control tower at this level involves customers, sub-contractors/agencies and suppliers. This can be purely for information purposes, but can also involve them working on the system, achieving supply chain optimization across multiple companies. For example, sub-contractors can identify the most attractive options from their perspective.

- Cross-Supply Chain Level: Utilizing a control tower across multiple supply chains is the final level. From a theoretical point of view, this is the ultimate way of working, but from a practical point of view it is challenging: horizontal cooperation rules are required for fair profit-sharing to determine what information is allowed and necessary for proper optimization and whether a third (central) party is involved in the execution.

Adding Optimization with the Control Tower

A number of opportunities result from adding optimization with the control tower, such as using it to construct better centralized plans in advance or to re-optimize and reschedule the plan during execution (e.g., by presenting proposals for the best alternatives or to continuously recompute the ETA), and to respect all dependencies and restrictions during any scheduling calculations, supporting all complex logistic concepts.

What are the results of optimizing a supply chain by using a Control Tower?

The main benefits of using a control tower to optimize a supply chain are:

- Centralized data and optimization functions

- Real-time visibility, transparency and overview

- Generated dynamic optimization power

Thanks to the Control Tower with optimization capabilities, companies can achieve:

- An increase in required deliveries without the vehicle requirement increasing accordingly

- Better insight into creating pick stage plans which greatly increase the accuracy and floor utilization Better route build and trailer utilization

- Reduction in miles travelled

- Reduction in fuel costs and CO2 emissions

- Improved communication and management overview

- Impressive cost savings within a short period

Why Contact ORTEC to Create or Optimize a Control Tower?

ORTEC has created a transportation control tower to visualize supply chains from end-to-end and to optimize all aspects of transportation. Implemented at consumer goods companies, retailers, and logistics service providers, the ORTEC Control Tower is designed to give dispatchers and managers a comprehensive view of operations at their fingertips — an environment that ensures optimal resource management and heightened service levels.

ORTEC enables centralized planning and dispatch with a suite of advanced features that cater to the dynamic needs of logistics professionals, from management to customers to suppliers. By providing real-time information, like the current estimated time of arrival, they can use data insights to optimize each section of the supply chain.

Key Features that Empower Your Logistics Team

- Real-Time GPS Tracking: Leverage live GPS data from telematics for real-time vehicle monitoring, enabling dispatchers to make quick, informed decisions.

- User-Friendly Dashboard: Utilize an intuitive interface that presents critical information at a glance, enhancing the dispatcher experience by simplifying access to essential data.

- Comprehensive KPI Dashboard: Keep track of Key Performance Indicators—including route status and on-time stops—to drive continuous improvement across operations.

- Customizable SLAs: Tailor customer Service Level Agreements to present the most relevant data and metrics, ensuring alignment with specific operational goals.

- Alerts and Notifications: Stay ahead of issues with real-time notifications for significant events, such as driver alerts or route modifications, facilitating proactive management.

- Collaboration Tools: Foster seamless communication among dispatchers, drivers, and management, ensuring everyone is aligned and informed.

Unlock Seamless Logistics Management

The ORTEC Control Tower transforms logistics management by integrating real-time insights with data-driven decision-making processes. Here's how:

- Proactive Management: Address potential issues before they become problems, maintaining smooth operations and minimizing disruptions.

- Improved Efficiency: Optimize resource allocation with real-time visibility into vehicle availability, reducing unnecessary downtime and improving overall performance.

- Streamlined Communication: Enhance collaboration across teams, leading to faster response times and heightened customer satisfaction.

- Scalability: Adapt to growing data volumes and evolving operational needs, ensuring the solution grows with your organization.

Explore Further

Learn more about our supply chain optimization solutions for consumer goods and manufacturing, wholesale and retail, and logistics services organizations.

Discover Our Solutions

Experience the transformative benefits of ORTEC Control Tower firsthand. Schedule your demo today and unlock the potential of seamless logistics management.